Time:2025-11-20 08:11:15 Source:Sanjian Meichen Steel Structure

High-Performance Engineering for Demanding Applications

Steel structure failures in energy plants are rarely about obvious mistakes—they stem from hidden risks, overlooked details, and false savings, which can cost millions and harm your reputation.

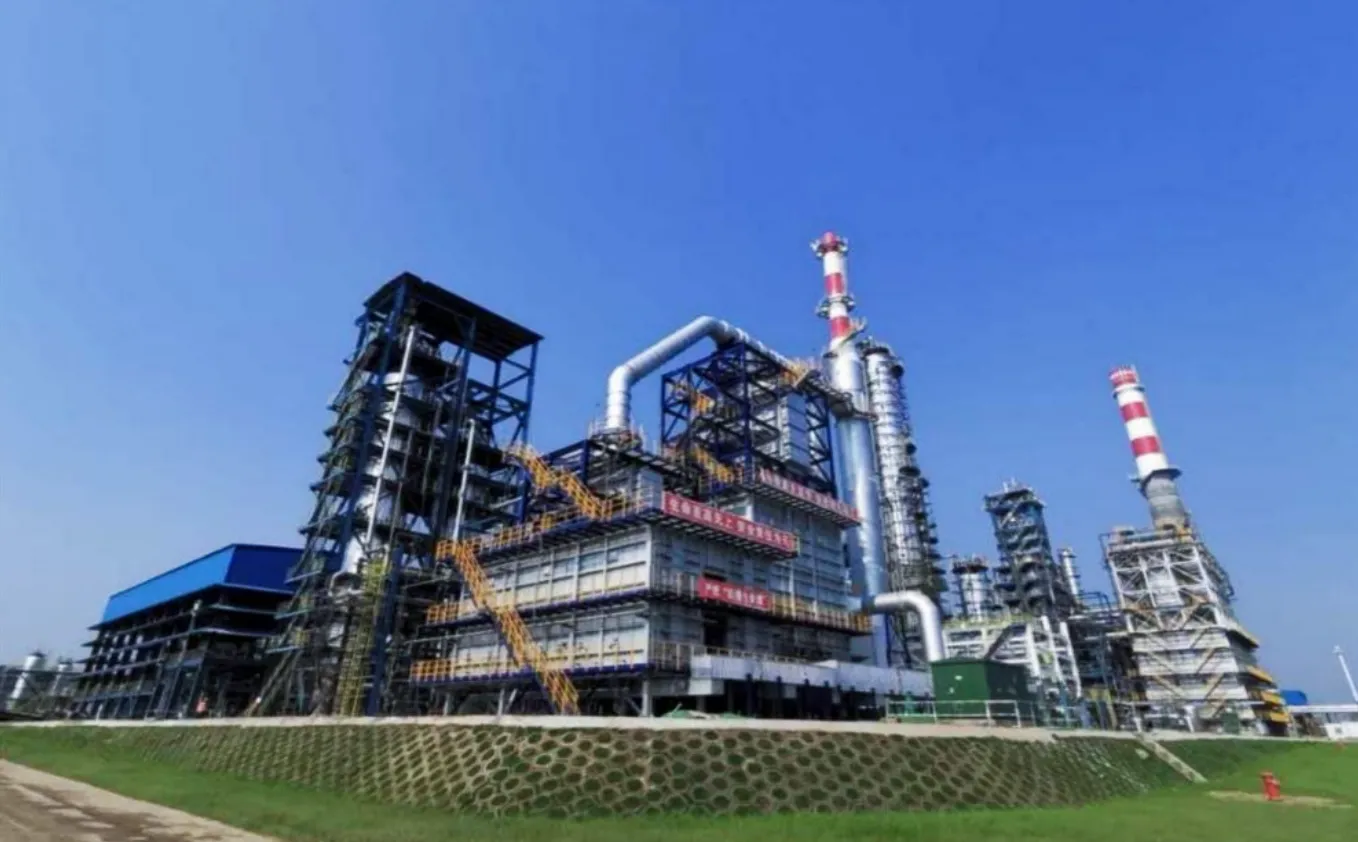

Heavy equipment support structures for petrochemical and energy plants must handle extreme loads, dynamic vibration, severe corrosion, and complex maintenance needs. Proper design, construction, and lifecycle planning prevent downtime and catastrophic failures.

When every hour of downtime means lost revenue, engineering for reliability is the only way forward. I’ve seen top-tier companies win projects not with the fanciest designs, but through risk management, hands-on inspections, and lifecycle thinking. Read on for what truly sets high-performance heavy equipment supports apart—and the buyer power moves that give you control.

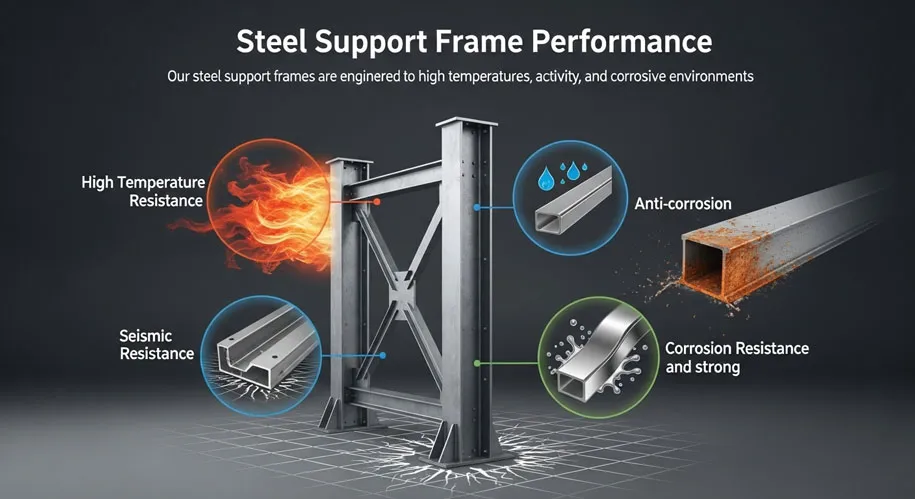

Steel supports for heavy equipment face not just gravity, but also vibration, thermal expansion, chemical attack, and unpredictable installation challenges. Overlooking these factors leads to failures and cost overruns.

Heavy equipment support in petrochemical and energy projects must manage point loads from machines weighing hundreds of tons, resist shifting due to vibration or movement, and withstand harsh chemicals, heat, and fire exposure every day. Unlike standard building frames, these structures support both static and dynamic loads and need to fit exactly with foundations, utilities, and mechanical systems. Most failures I’ve witnessed happened not from ignoring codes, but from not anticipating all the loads and external conditions in real-world operation.

In my first years reviewing plant certifications, I would sometimes see “code-compliant” supports with cracks or unexpected rust just three years into operation. The code covers the basics; safety comes from preparing for the realities of operation—installations that go wrong, chemical spills, unplanned equipment vibration, and decades of exposure to the elements. Most of all, correct foundation connections, redundancy, and forward-thinking upgrades are what save projects from future disaster.

| Load Type | Description | Common Failure Mode |

|---|---|---|

| Point/Concentrated | Heavy machines, tanks, reactors impose intense loads in small zones | Local buckling, plate yielding |

| Dynamic/Vibration | Equipment start/stop, rotating machinery, vehicle impacts | Fatigue cracks, connector loosening |

| Thermal Movements | Heating/cooling cycles expand and contract structures | Connection failures, weld cracking |

| Corrosion/Fire | Chemical/saltwater exposure, heat from fire | Hidden rust, fastener weakening |

I urge project managers to review support structures by walking the jobsite or 3D model—look for “what if?” scenarios. Plan for crane lifts, expected equipment swaps, acid leaks, and unexpected impacts. Each scenario adds safety and value, not just upfront, but during every outage and upgrade over decades.

Regulatory codes are the starting line, not the finish. Site-specific risks, dynamic forces, and real-life stressors often go far beyond the code requirements.

Most failures I’ve audited were “to code.” But during heater startups, compressor swaps, or bad storms, structures saw loads that codes never described. For critical assets, demanding more than the basic requirement is a must. That means analyzing fatigue, requiring redundancy, and planning for rare events like emergency lifts or process upsets. Smart clients use codes as a benchmark, then build in their own risk factors and maintenance needs.

To go beyond the code, I always begin by reviewing not just the OEM drawings but also the plant’s real operation history. Have you had equipment swapped out with heavier units? Do you see regular vibration in one particular pump bay? Codes assume everything works as drawn, but real-life never does. For example, I have worked with a major US refinery that retrofitted vibration isolation pads and added beam redundancy after just five years of “to code” operation, once micro-cracking showed up during shutdowns.

Fatigue Analysis: Rotating machinery—even the “quiet ones”—generate months of micro-movement. Add vibration absorbers and specify high-fatigue weld detail if you want your supports to last.

Redundancy: For major vessels or lifts, don’t rely on a single support member. Add backup beams or pins where possible.

Erection & Maintenance Loads: Think about temporary installation stresses with cranes, hydraulic jacks, or heavy lifts. Plan for these so you do not cause hidden damage before the plant is even running.

The most successful clients I work with ask: “How will we maintain, inspect, and eventually upgrade this support?” Building in these answers early prevents long-term risk and delivers value year after year.

Galvanized steel, Duplex Stainless, and fully-welded details offer the best corrosion resistance for steel supports exposed to chemicals or the elements. Painted systems can fail quickly in aggressive environments.

Choosing materials for chemical plants or offshore substations is not about saving a dollar today—it’s about avoiding massive repair costs and shutdowns later. I have repeatedly seen projects that went with “spec paint” systems only to repaint and repair within two years, especially at connections where water and chemicals collect. Galvanizing, high-quality stainless, and full penetration welds (especially in splash zones) give decades of service. Paint plus ongoing inspection is OK for dry interiors, but in exposed or high-corrosive areas, upgrade materials right from the start.

| Option | Upfront Cost | Typical Lifespan | Maintenance Needs | Best Use Cases |

|---|---|---|---|---|

| Painted Carbon | Low | 3-8 yrs | High—regular touchup | Interiors, low corrosion zones |

| Galvanized Steel | Moderate | 15-30 yrs | Minimal | Outdoors, splash zones, pipe racks |

| Duplex Stainless | High | 30+ yrs | Minimal | Saltwater/chemical, firefighting area |

When a supplier pushes “standard paint” for something sitting over acid tanks or near cooling towers, ask—“What is the total cost of ownership for the next 20 years?” That challenge almost always leads to smarter, safer upgrades.

Structure design must think ahead for heavy lifts, future equipment swaps, and plant growth. Modular, bolt-on, and accessible details can drastically reduce shutdown time and upgrade cost.

Most tender documents cover the operational phase but ignore erection and future upgrades. In my experience, every successful project I’ve seen includes detailed “erection sequence” documentation and preplanned bolting points for future growth. Design that skips these steps leads to forklift jams, bent beams, or costly shutdowns later.

Erection sequence plans, with temporary bracing loads modeled, so you don’t stress the steel before operation.

Bolt-on interfaces or splices for future capacity increases, rather than all-welded rigid designs.

Removable platform sections and access routes for easy maintenance and equipment lifting.

Modular beams that allow “cut and extend” without shutting down the entire structure.

I’ve seen clients save millions on plant expansions because their original support layout included pre-drilled holes and docking points for upgrades. This “future-proofing” means fast, safe changes without expensive plant outages.

Third-party inspection and documented material tracing prevent costly failures from hidden defects, unqualified welders, or low-quality steel bought on price alone.

The weakest link in any steel structure is the component you didn’t check. All my toughest “root cause” investigations found issues in bolts that weren’t tested or welds documented only on paper. Strong structures come from mill certificates, traceable fasteners, and on-site ultrasonic weld tests—not just specs on a drawing.

Always demand documented mill origin and batch testing for anchor bolts and major plates.

Employ third-party weld inspectors for complex or mission-critical work.

Mandate site visits at both fabrication and installation stages—physical presence always identifies issues that remote reviews overlook.

Consider digital twin models to check fit and coordinate between trades before making steel.

If you inspect only on paper, you will pay the price later. Real inspections, both at the factory and onsite, are what separate flawless project delivery from last-minute cost overruns.

Bundle design and fabrication, insist on engineer project visits, and use 3D digital twins to prevent fit-up and schedule surprises.

The most successful procurement managers—those who win both price and quality—create direct feedback loops between engineering, fabrication, and site management. Splitting design and manufacturing leads to finger-pointing and missed handoffs. When you bundle, the same team answers for the entire process, reducing gaps and delays. Requiring engineer visits, instead of just submitting drawings, saves time by catching site issues before they cause work stoppages or RFIs.

Bundle design and supply, with firm KPIs on delivery and tolerance—more accountability, less risk.

Require digital twin modeling to flag clash points before fabrication starts.

Maintain a pre-approved suppliers list based on recent performance, not just price.

Push for site-based issue resolution and early involvement of your steel partner in planning meetings.

When procurement is hands-on and keeps close tabs on both manufacturing quality and jobsite realities, projects finish faster and problems become learning moments, not lasting failures.

Successful heavy equipment supports are built on more than strength; they require forward thinking, proven materials, true inspection, and integrated procurement to weather decades of challenge.