Ensure Safe Flare Operations and Maximize Facility Reliability

In refineries, petrochemical plants, and large industrial facilities, flare systems are critical for safe emission and environmental protection. The flare stack structure not only supports high-elevation flares but also carries complex pipelines and auxiliary equipment.

Choosing the right steel support framework ensures:

Higher safety factor – minimizes flare tilting and pipeline deformation

Lower maintenance costs – durable, corrosion-resistant steel reduces long-term expenses

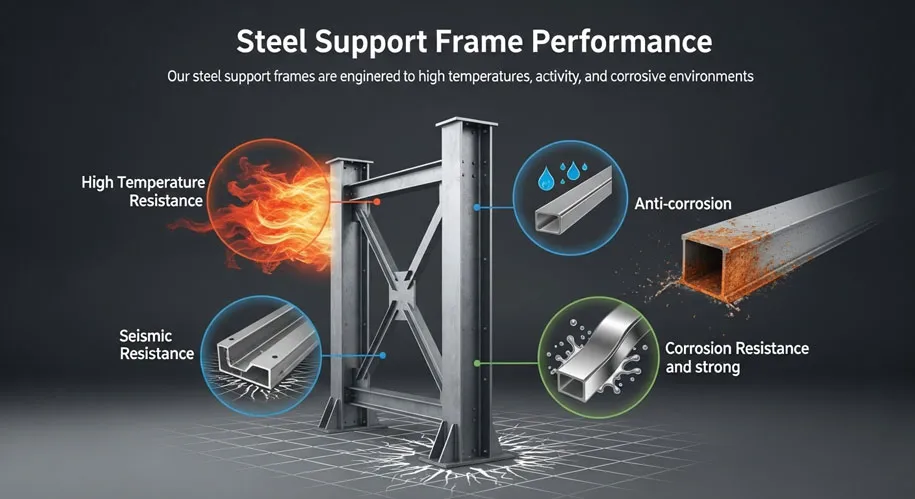

Greater environmental adaptability – withstands high temperatures, strong winds, earthquakes, and harsh climates

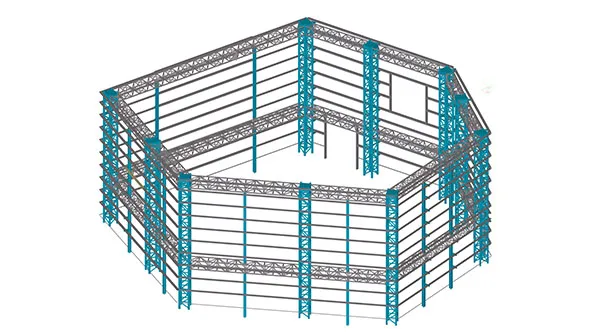

Truss or lattice design provides lightweight yet high-load-bearing capability

Can withstand typhoons, seismic forces, and high-temperature loads, ensuring long-term stability of the flare stack, flare tower steel structure, and flare support structure

Made from weather-resistant steel with multi-layer protective coatings

Suitable for extreme environments, including corrosive gases, desert, or coastal conditions

Factory prefabrication with precise assembly

Significantly reduces construction time and minimizes on-site risks

Equipped with inspection platforms, ladders, and safe walkways

Facilitates routine inspection, maintenance, and future upgrades, ensuring efficient operation

20+ years of steel structure manufacturing experience – serving petrochemical, energy, and large industrial projects

Full digital workflow with Tekla Structures – high precision, minimal errors, and reduced rework

High production capacity – annual steel output exceeds 50,000 tons; can handle multiple large flare stack and support structure projects simultaneously

International standard certifications – ISO9001, Environmental Management, and Occupational Health & Safety, ensuring compliance with global requirements

Imagine your project:

High-elevation flares burning stably, unaffected by strong winds, sandstorms, or high-temperature corrosion

Faster project delivery, convenient operation and maintenance

Significantly reduced safety risks and enhanced operational reliability

With Henan Sanjian Meichen, you get high-precision, durable, and lifecycle-safe steel flare stack and support structures, tailored to your project needs.

Engineering design drawings and feasibility analysis

Customized flare tower steel structure and flare support structure design

Free technical consultation and project support

WhatsApp / Phone: +86 13383791128

Email: info@meichensteel.com

Henan Sanjian Meichen – Your trusted partner for safe, reliable, and high-performance flare steel structures.

Steel Structure Workshop Solutions

Steel Warehouse Solutions

Heavy Steel Structures for Equipment

Indonesia North Kalimantan Aluminum Plant Project

Petroleum & Natural Gas Riveting and Welding Factory

Smart Furniture Production Base Construction for Luoyang Kefeiya

Steel structure warehouse building

Steel Structure Factory & Workshop Buildings