Our Steel Structure Workshop Solutions for Your Industrial Project.

Steel structure workshops are versatile, durable, and cost-effective solutions for various industrial production and storage needs. Whether you're building a manufacturing plant, a heavy-duty equipment storage facility, or an assembly line, our custom-designed steel structure workshops offer the flexibility to meet your unique requirements.

Fast Construction Time: Our steel workshops typically deliver within 3-6 months, with expedited options available to shorten delivery to just 2-3 months for urgent projects.

High Durability: Constructed with high-strength steel, our workshops are built to withstand harsh weather conditions, offering excellent corrosion resistance, wind resistance, and seismic stability, ensuring long-term reliability.

Tailored Designs: We offer customized layouts, functional areas, and equipment installation zones, ensuring your steel workshop aligns perfectly with your production workflow and operational requirements.

"Project Timeline: From Design to Completion"

Understanding the key project phases helps streamline your planning. Our clear project schedule ensures timely delivery and high-quality results.

| Stage | Duration | Description |

|---|---|---|

| Initial Consultation & Design | 1-2 weeks | Finalize workshop type, size, and functional areas. |

| Design Confirmation & Approval | 2-3 weeks | Incorporate feedback and approve final design. |

| Steel Structure Manufacturing | 6-8 weeks | Manufacturing of steel components using advanced techniques. |

| Shipping & On-Site Installation | 4-6 weeks | Arrange shipping and complete on-site installation for timely delivery. |

| Expedited Delivery Option | 3-4 months | Accelerate delivery time for urgent requirements. |

"Choose the Perfect Steel Structure Workshop for Your Needs"

We offer several types of steel structure workshops, each tailored to your specific industrial requirements.

Production Workshops

Designed for manufacturing processes, these workshops optimize the layout for production lines, equipment installation, and smooth workflow.

Example: Automotive parts manufacturing or electronics assembly.

Heavy-Duty Workshops

Built to accommodate large equipment, heavy machinery, or industrial processing, these workshops feature reinforced floors and load-bearing structures for optimal performance.

Example: Steel processing or large-scale machinery storage.

Assembly Workshops

These versatile workshops support assembly lines, workstations, and storage areas for efficient assembly, inspection, and packaging operations.

Example: Consumer electronics assembly or product packaging.

"Understanding the Cost Structure of Steel Structure Workshops"

We offer transparent cost breakdowns to help you plan your project budget efficiently.

| Cost Category | Description | Estimated Cost Range |

|---|---|---|

| Material Costs | Steel, coatings, fireproofing, and insulation materials. | $550000- $570000 |

| Shipping Costs | International shipping, especially from China to Africa. | $110000 - $113000 |

| Installation Costs | On-site construction, equipment installation, and project management. | ******* |

| Total Budget Range | Varies depending on workshop size, customization, and shipping distance. | $750000 - $850000 |

"Our Steel Workshops Meet Global Standards"

We ensure that every steel structure workshop meets stringent international standards, guaranteeing quality and long-term performance.

ISO 9001 Certification: We follow strict quality management processes throughout the design, manufacturing, and installation phases.

ASTM Standards: Our workshops comply with American Society for Testing and Materials (ASTM) standards, ensuring reliable materials and performance.

EN Standards: We adhere to European standards (EN) for the highest level of design and manufacturing quality.

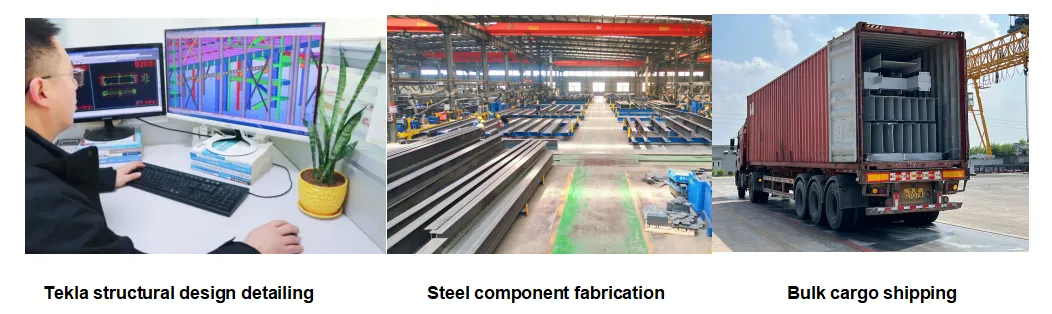

Our Rigorous Manufacturing and Quality Control Process

We maintain strict quality control throughout the manufacturing process to ensure the highest standards for every steel structure workshop.

Design Review & Material Testing: Each design is thoroughly reviewed, and all materials undergo compliance testing.

Process Quality Control: From cutting to welding to coating, each step is monitored to ensure strength and durability.

Final Inspection & Testing: Every component is inspected for accuracy and strength, and necessary tests (compression, seismic resistance) are performed.

7. Case Studies and Customer Feedback

"Real-World Examples of Our Steel Workshops"

Our steel workshops have been successfully implemented in various projects. Here are a few examples of how we've helped our clients achieve their goals:

We offer extensive support post-delivery to ensure your steel workshop operates smoothly.

We make it easy for you to get in touch and request a detailed quote.

Steel Warehouse Solutions

Heavy Steel Structures for Equipment

Indonesia North Kalimantan Aluminum Plant Project

Petroleum & Natural Gas Riveting and Welding Factory

Smart Furniture Production Base Construction for Luoyang Kefeiya

Flare Stack Structure

Steel structure warehouse building

Steel Structure Factory & Workshop Buildings