Time:2026-01-16 02:16:15 Source:Sanjian Meichen Steel Structure

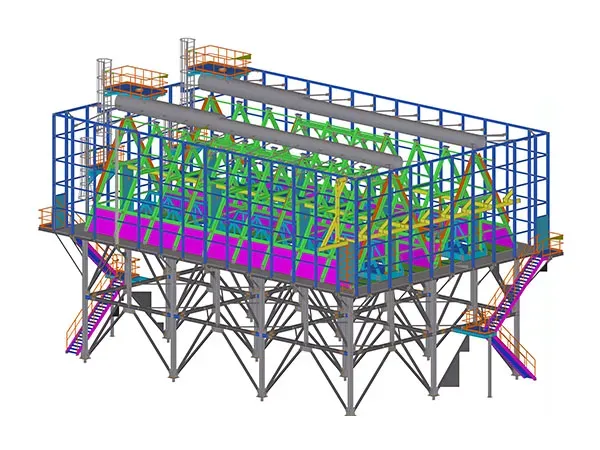

Petrochemical equipment is huge and packed tight. Crews lose time and take risks. Poor platforms drain budget. I design steel platforms that cut downtime, raise safety, and keep maintenance track.

Steel access platforms matter because they give safe, direct reach to valves, instruments, and manways on large units. They reduce climbing, avoid pipe crossings, and speed inspections and repairs. Good platforms cut unplanned shutdowns, improve compliance, and support upgrades without scaffolds or heavy rework.

You control cost and schedule through platform decisions. I will show clear design moves, real failures, fixes, and a buying checklist you can use now. Keep reading, because each section gives tools you can apply today.

Huge reactors and dense pipe racks block reach. Crews improvise and risk injury. A clear steel platform plan removes obstacles, shortens routes, and keeps operations and maintenance simple and safe.

Access platforms matter because they create standard, direct paths to real work points. I set walkway widths, stair rises, landing spacing, and egress routes for actual tasks. This cuts climb time, prevents slips, and removes temporary scaffolds during inspections, sampling, and routine repairs.

I start with routes. I set walkways at 900–1200 mm based on traffic. I keep clear width at pinch points. I avoid hot lines and moving parts near walkways. I place landings where crews stop to work. I use consistent stair pitch for steady flow. I fix riser height and tread depth so steps feel the same. I add crossovers to reach valves that sit across busy pipe runs. I place work platforms at gauge height, not knee or shoulder height. I include tool shelves and cable hangers at work spots. I provide two egress routes when space allows. I mark paths with color and simple signs. I set anchor points for fall protection near high-risk tasks. I add night lighting along routes. I test the full path with operators before sign-off. Their steps reveal blind corners and poor reach. I change small details at once. That walk reduces time and removes risk in daily work.

Rust, change, and safety drive cost. Cheap steel looks fine at handover but fails early. Better design choices stop corrosion, allow upgrades, and protect people without heavy weight.

Choose hot-dip galvanizing or proven coatings by zone. Use modular bolted nodes and reserved seats for future spans. Add anti-slip grating, continuous handrails, toe boards, and anti-climb guards. Model static and dynamic loads. Tune members and connections to cut steel safely.

Corrosion control is first. I map zones by exposure. Splash zones, salt air, and chemical vapor get hot-dip galvanizing with target zinc thickness. I add a topcoat when the chemical set attacks zinc. Dry interior zones get a simpler system with strong prep and proper film build. I avoid thin paint that peels in year three. I design so water drains and dirt does not trap. I seal cut edges. I isolate dissimilar metals to prevent galvanic attack. Modularity is next. I use bolted nodes, slotted plates, and splice flanges. I reserve beam seats for future spans. I standardize stair flights and landings. I design removable panels for large valve changes. I use quick column bases that align with pre-embedded anchors. Safety is built in. I pick serrated grating for wet areas. I run handrails continuous with mid-rails and toe boards. I add anti-climb mesh near hot equipment. I install self-closing gates at ladders. Loads and vibration matter. I check people loads and equipment loads. I include dynamic loads from pumps, drivers, and maintenance. I use finite element models to tune member sizes, deflection, and connection types. This trims steel without risk. I follow local codes, OSHA, and client standards. Fireproofing goes on columns where required.

I see platforms cut and re-welded during upgrades. I see paint fail in year three. I fix these with plug-in steel, real galvanizing, and complete safety that passes acceptance.

One park rebuilt with modular columns and slotted beams. Work fell from 120 to 40 crew-days. Another plant switched from paint to galvanizing and avoided full rebuilds for a decade, with only local touch-ups.

A head plant tried to change a reactor loop. Every platform was welded tight to frames and pipes. The crew cut, re-fit, and re-welded week after week. The schedule slid. Indirect loss went past two million. I led a rebuild. We used plug-in columns with slotted bases. We set hollow beams with slotted seats. We carried standard stair flights and landings like kits. We bolted, aligned, and checked routes in hours, not days. We finished in forty crew-days instead of one hundred and twenty. Another client used basic paint for corrosion protection. In year three the bolts froze. The grating lifted. Touch-ups could not stop the spread. We switched to hot-dip galvanizing and a smart topcoat for harsh zones. The platform ran a decade with only local fixes. Safety omissions also appear. A contractor skipped anti-climb guards and toe boards to save money. The platform failed acceptance. We installed guards, toe boards, and self-closing gates. The team passed at once. I now insist operators walk the route before sign-off. Their findings drive small changes that prevent big risks.

Schedules are tight. Mistakes cost days. The right supplier protects cost and safety. I use a clear checklist that exposes weak offers and confirms real capacity.

Ask for petrochemical case histories, site surveys, and design development. Require stamped load, seismic, and fire reports. Check production, quality, coating, and lead time. Prefer bundled stairs, ladders, anchors, and embeds with service commitments.

I begin with proof. I ask for petrochemical case histories with dates, photos, and references. I request a site survey. The team must visit, measure, and coordinate with process, civil, and electrical. I want a design development package with clash checks. I require load, seismic, and fire reports stamped by a qualified engineer. I confirm production capacity. The factory must cut, weld, and galvanize at scale. I review quality. I ask for welding procedures, welder certificates, NDT records, and torque reports for bolted joints. I check coating specs by zone. The supplier must state zinc thickness and paint systems. I ask for shop drawings with every hole, splice, and node shown. I review fit-up plans for fast install. I prefer bundled solutions. Stairs, ladders, gates, anchors, and embeds come in one package. I set service terms. I define response time for repairs and field fixes. I ask for spare kits for bolts, gratings, and gates. I confirm warranty terms. This checklist filters weak bids and protects total cost over years.

Buy platforms for life, not price. Choose corrosion control, modular design, and full safety. Pick proven suppliers. You will gain safer work, faster schedules, and lower total cost.