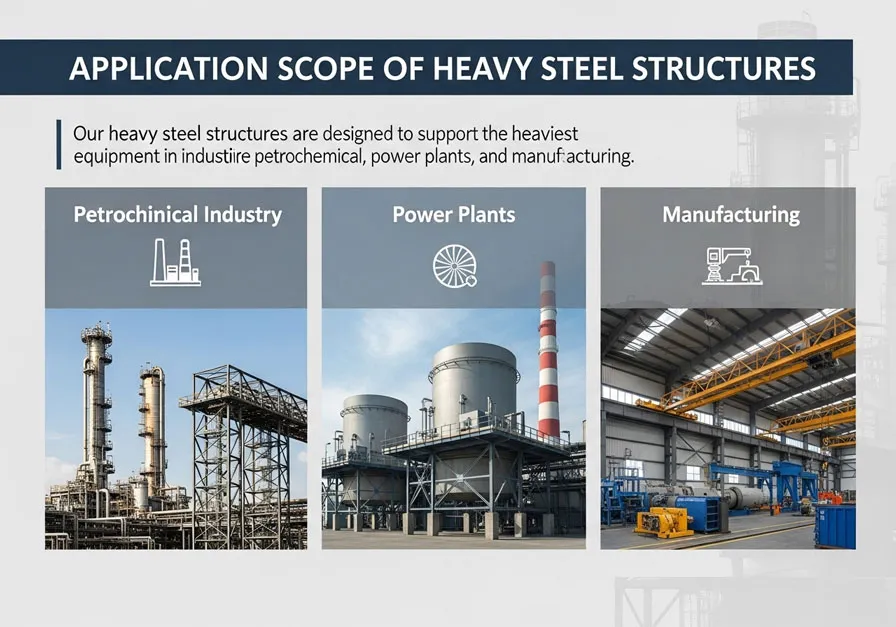

We specialize in providing heavy-duty steel frames capable of supporting equipment weighing hundreds of tons. Our custom designs ensure that your steel support structures meet the unique weight, size, and design specifications required for each project.

From large turbines to mining equipment and industrial machines, our structures offer maximum stability for all types of machinery in various industries.

At Henan Sanjian Meichen Construction Technology Co., Ltd., we are committed to delivering heavy steel structures and steel support frames with unmatched precision and reliability.

High Precision & Low Tolerance: Advanced CNC cutting and automatic welding ensure dimensional accuracy with minimal error, reducing on-site adjustments.

Premium Raw Materials: All steel materials are sourced from certified suppliers, guaranteeing strength, durability, and consistency for demanding applications.

Tekla-Based Digital Design: Using Tekla Structures, we provide full-process 3D modeling, minimizing design changes and ensuring accurate data transfer from modeling to fabrication.

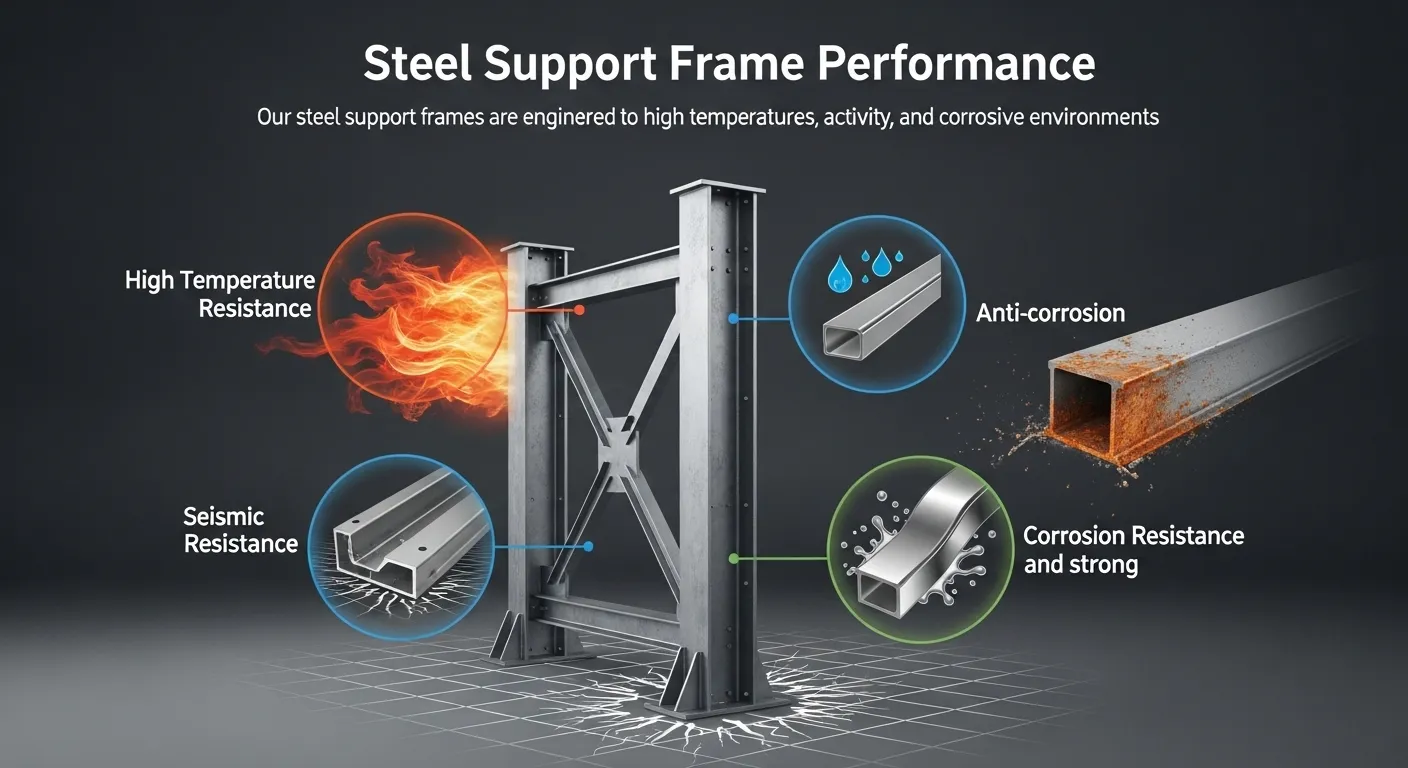

Stable & Robust Structures: Our steel support frames are engineered for superior load-bearing capacity and structural stability under heavy equipment and harsh environments.

Corrosion Protection: Surface treatment technologies, including sandblasting, hot-dip galvanizing, and anti-rust coatings, extend the service life of every structure.

Strong Production Capacity: With 50,000㎡ facilities and five modern production lines, we achieve an annual output of over 50,000 tons, enabling fast delivery for multiple large projects.

Advanced Fabrication Techniques: Automated assembly lines, precise welding, and strict quality control ensure each heavy steel structure meets international standards.

By combining precision engineering, premium materials, and cutting-edge processing technology, we provide steel support solutions that guarantee strength, safety, and long-term performance for critical industrial projects.

Steel Structure Workshop Solutions

Steel Warehouse Solutions

Indonesia North Kalimantan Aluminum Plant Project

Petroleum & Natural Gas Riveting and Welding Factory

Smart Furniture Production Base Construction for Luoyang Kefeiya

Flare Stack Structure

Steel structure warehouse building

Steel Structure Factory & Workshop Buildings