We specialize in custom-designed, manufactured, and supplied steel structures for large-span, cold chain, and multi-story warehouses.

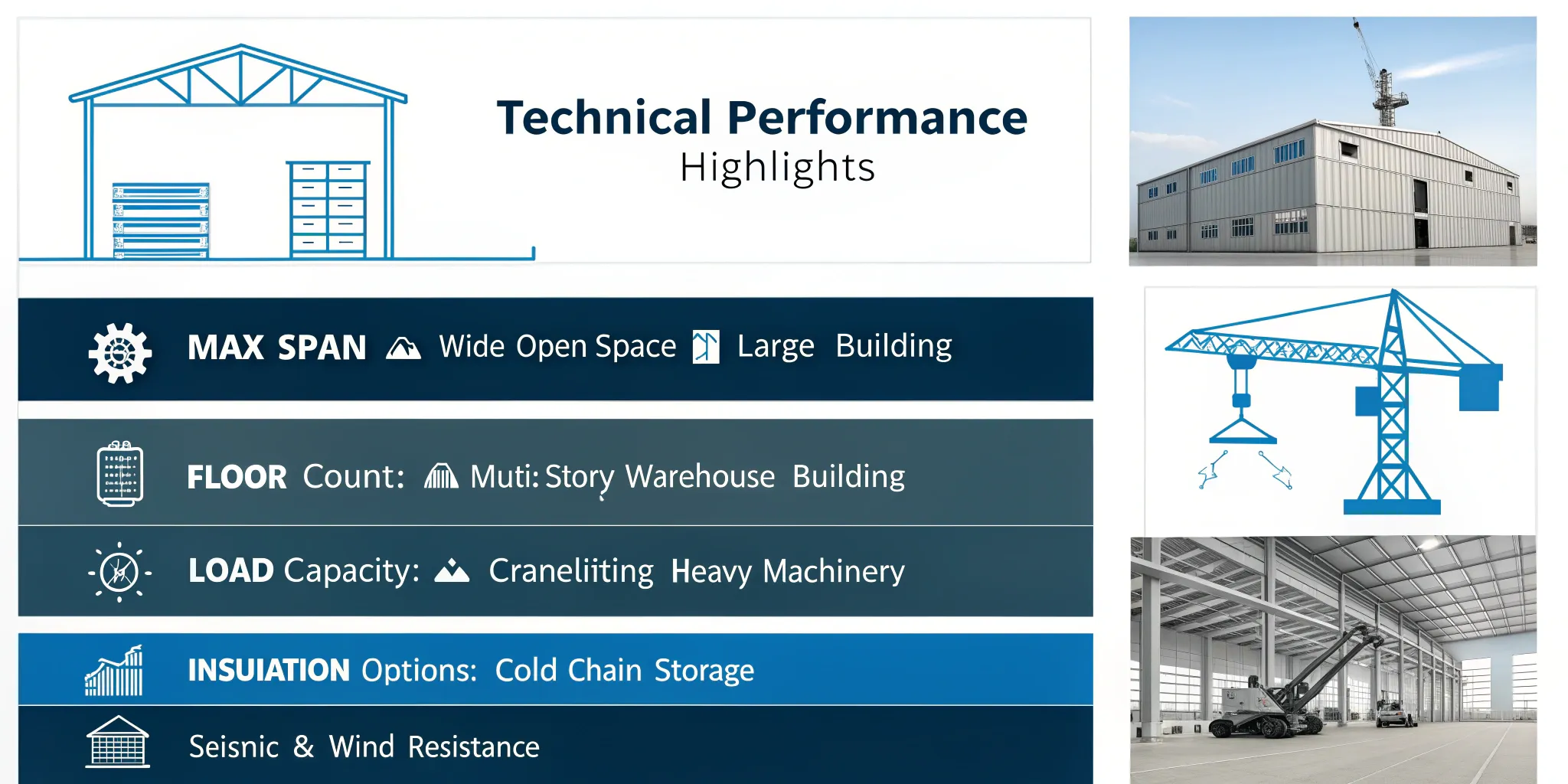

Seismic & Wind Resistance: Our designs meet the latest seismic and wind standards, ensuring the stability of the structure.

Steel structure warehouses offer numerous advantages over traditional buildings, especially when it comes to large-span and multi-story designs. Here are the key reasons to choose steel structures:

Flexibility: Steel allows for more flexible designs. Whether it's a large warehouse with a vast open space or a multi-story facility, steel structures provide the versatility to meet a variety of architectural and functional needs.

Durability: Steel is highly durable and resistant to the elements. Unlike traditional materials, steel does not rot, warp, or degrade over time, providing a longer lifespan for your warehouse. Steel’s ability to withstand corrosion is also enhanced by coating options like galvanization or painting.

Seismic and Wind Performance: Steel structures are known for their superior seismic resistance and can withstand high wind loads, making them ideal for locations prone to earthquakes or hurricanes.

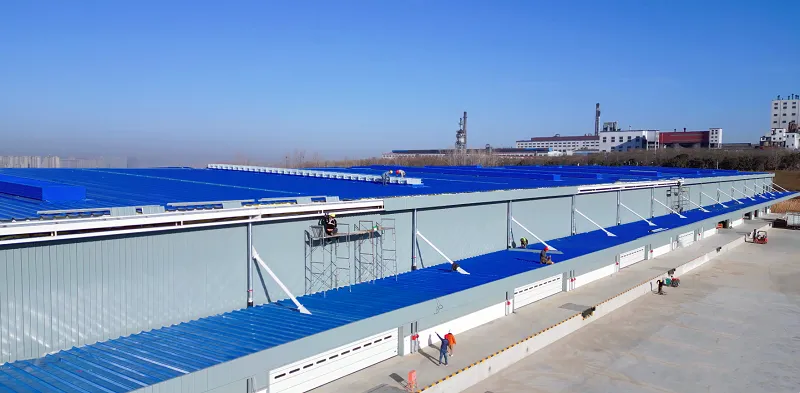

Faster Construction: Steel warehouses typically have a shorter construction timeline due to faster assembly of prefabricated components. This results in cost savings and allows your warehouse to be operational sooner.

Long-Term Value: While the upfront cost of steel structures might be higher than traditional buildings, the long-term benefits in terms of reduced maintenance, durability, and energy efficiency make it a more cost-effective solution over the life of the building.

The design process generally takes 2-3 weeks from the initial project requirements confirmation to the completion of preliminary designs. The timeline can vary depending on:

Project Complexity: More complex structures, such as multi-story warehouses or cold-chain facilities, may take a bit longer to design due to the additional engineering and planning involved.

Customization Needs: If your project requires highly customized features, like special insulation, heavy load capacity, or unique architectural elements, this will also add to the design time.

We ensure that the process is as quick as possible while maintaining high-quality standards. Our team works closely with you at every stage, providing regular updates and feedback to ensure that the design aligns with your specific needs and requirements.

Quality is our top priority. Here’s how we guarantee the highest standards for our steel structures:

Strict Quality Control: Every steel component undergoes multiple stages of inspection and testing during production to ensure they meet our CE certification standards. We also check for compliance with international quality norms, including load-bearing capacity, resistance to environmental stress, and other performance metrics.

Certified Materials: We use only high-grade steel that meets or exceeds industry standards. All materials are traceable, with certifications for their chemical composition, strength, and suitability for your specific application.

Engineering Expertise: Our designs are carefully engineered to handle the heaviest loads, withstand extreme weather conditions, and comply with all relevant safety codes. This includes wind, seismic, and snow load calculations.

Ongoing Support: We maintain quality throughout the project lifecycle, providing engineering support and addressing any concerns you may have during construction or after delivery.

Installation is not included in our service offering, but we provide full support to ensure the installation process goes smoothly:

Coordination with Your Installer: We work closely with your chosen installation team to ensure all components are delivered on time and that the installation is seamless. Our project managers will help guide the installer through the process, providing assistance where necessary.

Detailed Construction Plans: We supply comprehensive construction drawings and technical specifications to ensure that your installer has all the information they need. These plans include critical details on component placement, assembly instructions, and load-bearing requirements.

Engineering Support: Our team is available to provide technical advice throughout the installation phase. Whether it’s clarifying a design detail or troubleshooting a challenge, we’re just a call or email away.

Quick Troubleshooting: If any issues arise during installation, we offer quick response times to resolve them, ensuring minimal disruption to your project timeline.

Absolutely! We pride ourselves on customizing solutions to meet your specific needs. Here are some examples of how our steel structures can meet unique requirements:

Cold Chain Storage:

For warehouses that need to store temperature-sensitive goods, we offer specialized insulation options and temperature control systems. These solutions help maintain consistent internal temperatures for perishable products and ensure compliance with cold chain logistics standards. We also provide systems for humidity control when required.

Multi-Story Warehouses:

Our steel structures are designed to maximize vertical space, making them ideal for multi-story warehouses. We take into account your specific height restrictions, floor load capacity, and space optimization to create a design that maximizes usable area and meets all regulatory requirements.

Heavy Load Capacity:

If your warehouse needs to store heavy equipment, machinery, or large-scale inventory, our steel structures are designed to handle high load-bearing requirements. We customize the design to accommodate your specific load needs, ensuring that the structure remains stable and safe for heavy-duty use.

Custom Features:

Whether it’s roof pitch, safety features, or unique architectural elements, we can tailor our steel structures to fit the aesthetic and functional needs of your project. From specialized doors to custom skylights or ventilation systems, we work with you to design the ideal warehouse.

Steel Structure Workshop Solutions

Steel Warehouse Solutions

Heavy Steel Structures for Equipment

Indonesia North Kalimantan Aluminum Plant Project

Petroleum & Natural Gas Riveting and Welding Factory

Smart Furniture Production Base Construction for Luoyang Kefeiya

Flare Stack Structure

Steel Structure Factory & Workshop Buildings