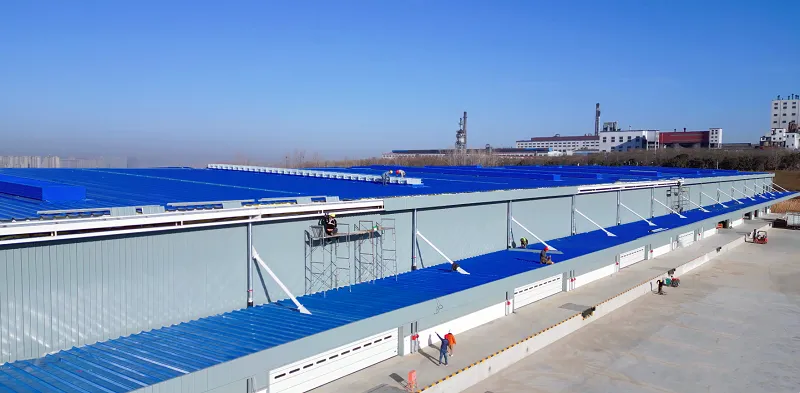

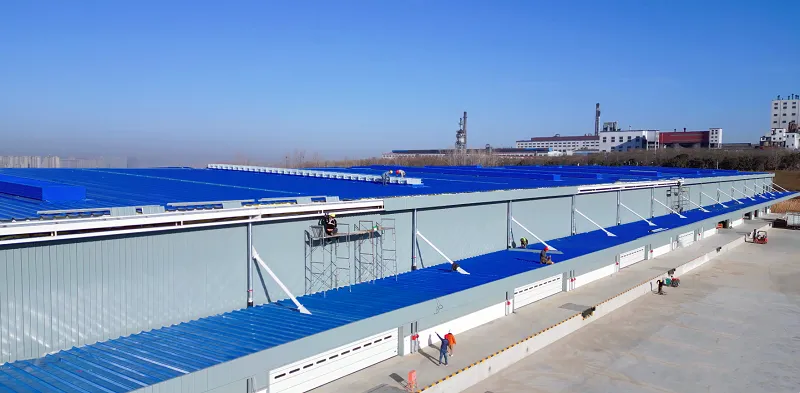

This modern steel structure warehouse was designed to balance efficient logistics operation and large-volume storage needs. With its spacious layout and structural durability, the facility supports high-performance material flow and warehousing operations.

Project Design & Structural Highlights

1. Efficient Structural System

The warehouse adopts a single-layer profiled steel insulated roofing system. The roof comprises a 0.6 mm thick YX66-394-788 light gray aluminum-zinc coated steel sheet as the outer panel, waterproof membrane, 75 mm insulation cotton, and steel mesh, offering excellent thermal insulation and waterproof performance.

The canopy roof uses the same insulated system to ensure long-lasting and efficient coverage.

2. Wall & Roof Design

Walls: Double-layer composite insulated walls. The outer wall uses 0.5 mm thick 840-type aluminum-zinc coated color steel sheets, while the inner wall uses 0.4 mm sheets, filled with 75 mm thick glass wool for thermal and sound insulation.

Daylighting Panels: 788-type twin 1.5 mm thick daylight strips with edge trimming provide abundant natural lighting, reducing energy consumption.

Ventilation: Equipped with 1.2-meter-wide thin ventilators on the roof to ensure airflow and maintain a healthy warehouse environment.

3. Steel Weight & Material Usage

The total weight of the steel structure is approximately 535 tons, including:

Welded H-Beam Main Frame: ~238 tons

Roof & Wall Purlins: ~188 tons

Secondary Components: ~109 tons

These steel components ensure the warehouse is structurally robust and suitable for heavy-duty storage requirements.

Project Advantages

Fast Construction & On-Time Delivery: Steel structure allows for rapid installation and ensures the project meets deadlines.

Energy Efficient & Eco-Friendly: The composite wall and roof system enhances insulation performance and reduces operational energy costs.

Flexible Space Layout: The large-span design enables flexible use of internal space to meet diverse storage needs.

About Henan Sanjian Meichen Construction Technology Co., Ltd.

Established in 1999, Henan Sanjian Meichen Construction Technology Co., Ltd. specializes in customized steel structure solutions for industrial parks, logistics warehouses, and commercial buildings. We offer integrated services covering design, production, and on-site construction to ensure every project meets the highest quality standards.

Contact Us Today to Plan Your Steel Structure Project

Looking for a high-performance, durable steel warehouse solution?

Henan Sanjian Meichen is ready to provide tailor-made services, ensuring your project is delivered on time and built to meet all technical requirements.

Get in touch with us now to start your custom steel structure journey.