This industrial construction project consists of two production plants (Plant 1 and Plant 2) with a total construction area of 77,703.04 square meters. Both plants feature a steel frame structure, designed to accommodate high production capacity while ensuring structural integrity and safety. The buildings have four floors, each with a height of 23.95 meters.

Key Details:

Plant 1 Area: 38,829.88 m²

Plant 2 Area: 38,873.16 m²

Structural System: Steel Frame

Fire Risk Category: D

Fire Resistance Grade: II

Seismic Design Intensity: 7 Degrees (0.10g)

Design Service Life: 50 years

Foundation: Pile cap foundation with a bearing capacity of 1000 kN per pile, using C35 concrete.

Steel Columns: Box-shaped steel columns with C30 concrete poured at the base for stability.

Steel Beams & Crane Beams: Welded H-shaped steel beams designed for high load-bearing capacity.

Roof & Wall Panels:

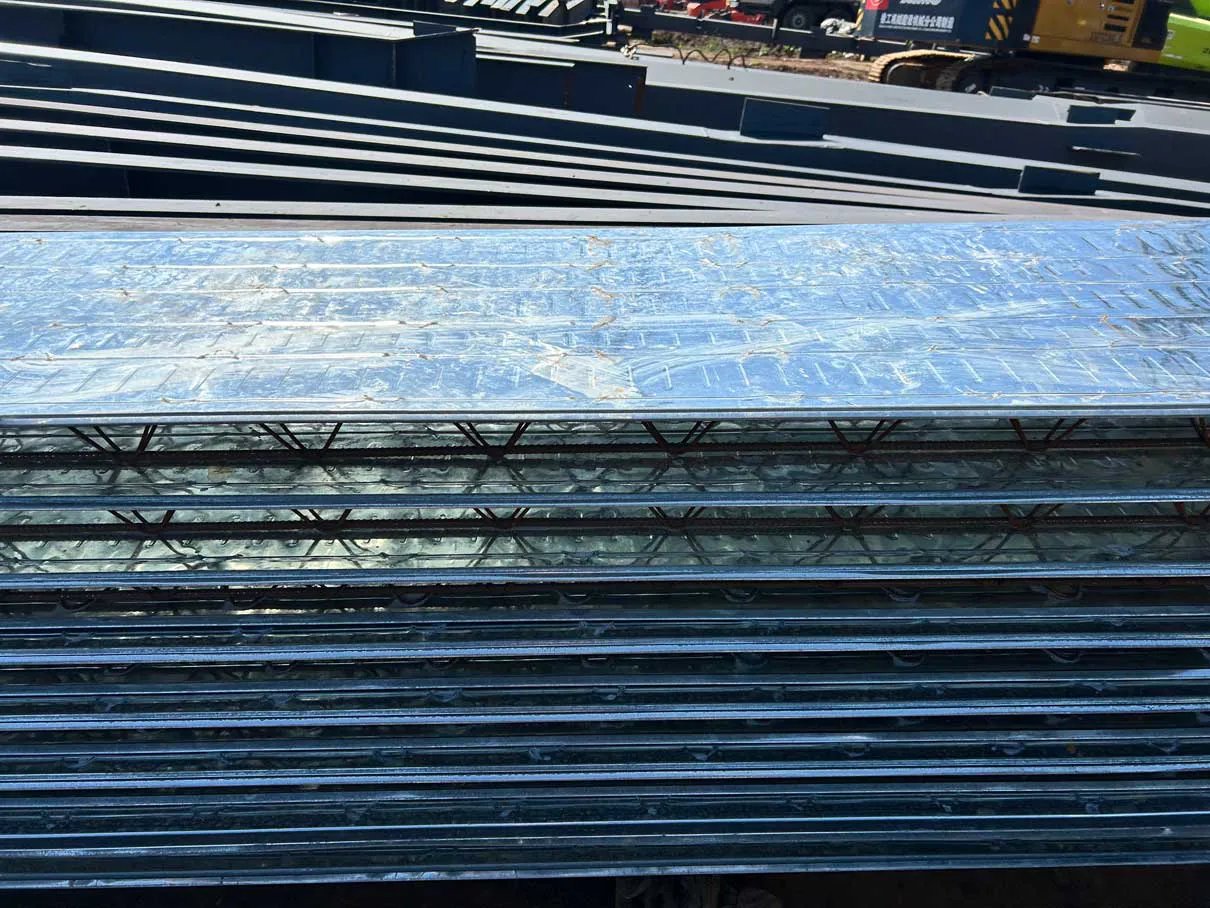

Roof: Single-layer composite insulated roofing with a galvanized steel sheet, glass wool insulation, and steel wire mesh.

Walls: Polyurethane edge rock wool composite insulation panels (0.5mm thick color-coated steel sheet outer layer, 75mm thick rock wool board, and 0.4mm thick color-coated steel sheet inner layer).

Flooring & Ceiling: Truss floor slabs and parts of the roof with C30 concrete poured onto the truss deck.

The main steel structure for this project is produced in our factory, using advanced automatic production lines. The process includes CNC cutting, assembly of H-shaped steel, automatic submerged arc welding, and shot blasting for surface preparation to Sa2.5 level. The steel components are then transported to the site for installation by our dedicated team.

Steel Material: Q355B low-alloy steel.

Welding & Bolting:

Welding: High-quality welds inspected at different levels based on load-bearing requirements. For dynamic load-bearing components, the weld quality is tested to Level 1 for tension and Level 2 for compression.

Bolting: High-strength 10.9S friction-type bolts are used for beam-column connections, with the friction surfaces shot-blasted for cleanliness.

Comprehensive steel structure production and installation services.

Precision in manufacturing and welding to ensure the highest quality and safety standards.

Use of advanced construction materials to meet industry standards for fire safety and seismic performance.

Designed for long-term use with a 50-year service life.

This project showcases our expertise in delivering large-scale industrial construction solutions, ensuring quality, efficiency, and structural integrity throughout the entire construction process.

Steel Structure Workshop Solutions

Steel Warehouse Solutions

Heavy Steel Structures for Equipment

Indonesia North Kalimantan Aluminum Plant Project

Petroleum & Natural Gas Riveting and Welding Factory

Flare Stack Structure

Steel structure warehouse building

Steel Structure Factory & Workshop Buildings