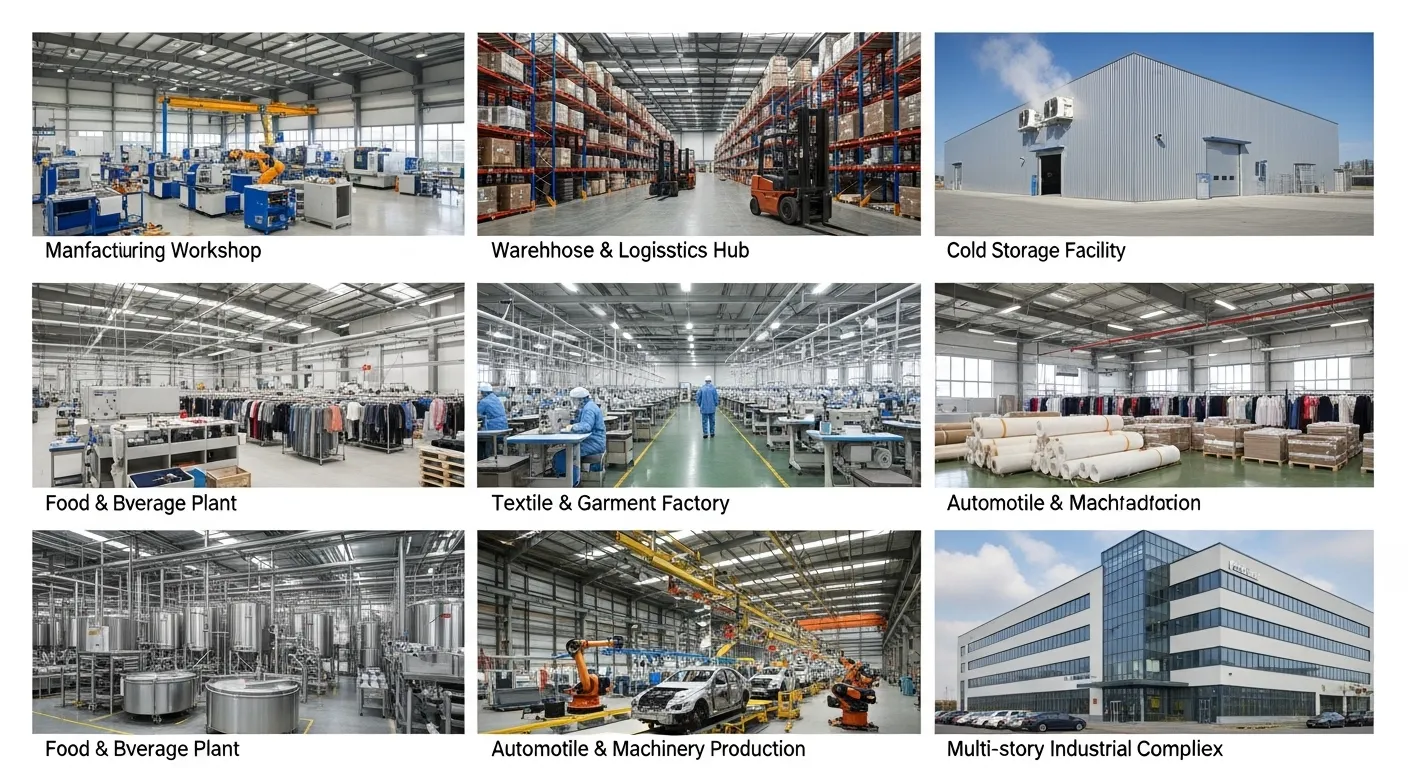

Multi-story industrial complexes

GREE Electric Manufacturing Park 26,244㎡ Temu Logistics Warehouse 18,851.18 m² German RV Production Park 33,000 m²

Q1: What is the typical cost of a steel structure factory building?

A: On average, the cost ranges between USD 40–80 per square meter, depending on building size, design complexity, and local installation costs.

Q2: How long does it take to complete a project?

A: Most medium projects (5,000–20,000㎡) can be delivered within 2–5 months, including design, fabrication, shipping, and installation.

Q3: Can steel factory buildings withstand earthquakes or typhoons?

A: Yes. All buildings are designed to international codes and can resist earthquakes (up to seismic zone 9) and typhoons (up to 150 km/h wind speed).

Q4: Is customization possible for different industries?

A: Absolutely. Each building is tailored to your specific production needs—whether for machinery workshops, food processing plants, or textile factories.

Q5: How is thermal insulation and fireproofing handled?

A: We offer sandwich panels with insulation layers, fire-resistant coatings, and ventilation systems to ensure energy efficiency and safety.

Q6: How is the building shipped and installed overseas?

A: All steel components are prefabricated, numbered, and shipped in containers. We provide detailed drawings, video instructions, or on-site engineers for smooth installation.

Q7: What after-sales services are available?

A: We provide 5–10 years structural warranty, lifetime technical support, and supply of replacement parts if required.

Steel Structure Workshop Solutions

Steel Warehouse Solutions

Heavy Steel Structures for Equipment

Indonesia North Kalimantan Aluminum Plant Project

Petroleum & Natural Gas Riveting and Welding Factory

Smart Furniture Production Base Construction for Luoyang Kefeiya

Flare Stack Structure

Steel structure warehouse building