Time:2025-11-21 03:10:23 Source:Sanjian Meichen Steel Structure

Steel platforms that fail to support heavy equipment can cause project delays, revenue loss, and safety risks. How can steel structures guarantee lasting integrity for high-load applications in every industry?

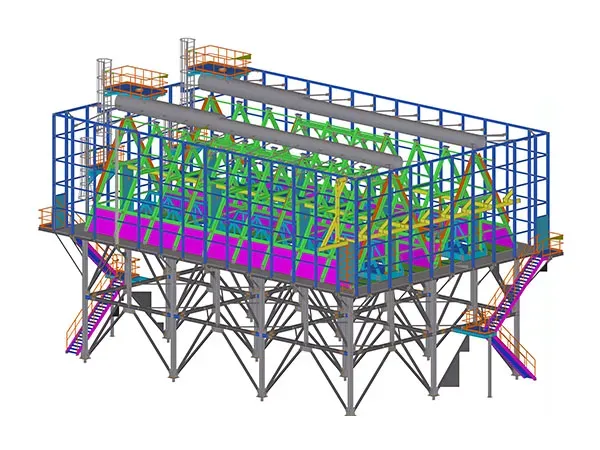

Steel structures ensure platform integrity by supporting both static (dead) and dynamic (live) loads, using certified high-quality steel, professional welding, reliable corrosion protection, custom design, redundancy, and rigorous third-party quality control. Together, these features deliver unmatched safety and durability for heavy equipment platforms.

Every project is different, but one lesson always holds true: nothing costs a company more than downtime from structural failure. When a platform cracks, vibrates, or shows signs of corrosion, operations stop, and repair bills can skyrocket. In my twenty years on the ground, I have seen how poor choices—rushed design, unverified materials, skipped inspections—lead to headaches that could have been prevented. That is why I am passionate about highlighting each critical element, so B2B buyers and engineers avoid costly mistakes and ensure their equipment stands strong for decades.

Let’s break down exactly what makes the best steel structures truly reliable for heavy equipment platforms.

Heavy equipment platforms are exposed not only to their own self-weight (dead load) but also constant movement, vibration, and personnel shifting (live loads). Calculating loads accurately is the core foundation of safe design.

Experienced engineers consider all possible combinations: the weight of installed equipment, vibration from motors or pumps, sudden impacts, and even extra weight from temporary upgrades or one-off changes. Leading industry practice is to build in an extra 25% margin above what normal operations require. This is vital because real-world usage often shifts over time; upgrades and changes are frequent. When a platform is engineered conservatively for future-proofing, it won’t need expensive retrofitting or reinforcement.

In my own work, I recall a mining facility where a platform, originally designed for static storage tanks, was repurposed for vibrating feeders. Standard load calculations were not adequate due to the new dynamic forces introduced. We had to bolster the structure to handle vibration, as well as prepare for heavier future machinery. The extra upfront calculation saved the client hundreds of thousands in repairs and downtime.

My advice: Insist your designer provides detailed load breakdowns and safety margins, factoring in every piece of equipment plus foreseeable upgrades. It’s the only way to guarantee longevity and safe operation.

Steel composition directly affects strength, ductility, weldability, and the ability to withstand environmental stresses. Global best practices call for using certified grades—like Q345B for China, S355 for Europe, or A992 in the US—each offering specific mechanical properties suited for structural platforms.

For major projects, material traceability is just as critical as certification. Each part of the platform must be documented from mill origin to final placement. This means mill certificates, batch numbers, and records of each heat, cut, and weld. If a supplier cannot provide these, they may be using substandard materials, recycled scrap, or mixing grades without your knowledge.

I learned about the power of traceability during one large logistics center build. Our client selected the lowest bid, but documentation quickly fell apart: material certificates were missing, welders could not confirm the origin of each beam, and several sections failed hardness and bend tests during inspection. The project was halted and required weeks of destructive testing and replacement. It was expensive and frustrating.

Since then, I always demand complete traceability and mill certification as part of the contract. It is your insurance policy against hidden flaws that can wreck a project’s reputation and structural safety.

In steel platforms, joints—both bolted and welded—are always the most critical points of potential failure. Poorly executed welds weaken with time, especially under heavy vibration or shock loads. Bolts without the correct grades, torque, or inspection lead to loosening and unexpected movement.

International standards like AWS (American Welding Society) or EN (European Norms) guide weld quality. But it is not enough to simply follow the book. Smart designers specify double bolting in high-stress areas, full-penetration welds for main load paths, and routine non-destructive testing (NDT) such as ultrasonic testing (UT), magnetic particle testing (MT), or dye penetrant testing (PT).

One project manager I know invested in extra joint testing and discovered several invisible cracks that standard surface inspections missed. Fixing these proactively avoided massive future failure. I always recommend a full “weld map”—a diagram showing every weld and its test result—plus records of bolt torque checks. These take a bit more time, but they are the best defense against downtime. In the end, the cost of professional connections is tiny compared to the cost of repairs, lost revenue, and safety violations if something goes wrong.

Steel platforms in industry face tough conditions: high humidity, acid fumes, chemical spills, abrasive dust, and even temperature cycling can break down protective layers or penetrate seams to attack the steel directly. Corrosion is the silent killer that often starts where you cannot see.

Standard practice is to specify corrosion protection methods tailored to the environment. Hot-dip galvanizing provides a durable barrier for environments with salt, pollutants, or moisture. For special applications—like chemical plants—a multi-layer industrial coating system (primer + midcoat + topcoat) works well. The premium option is a “duplex” system: galvanizing plus paint for maximum lifespan. Crucially, weld seam sealing and edge rounding must not be skipped. These tiny details are notorious for becoming early rust spots, causing the whole system to fail prematurely.

In one energy park project, a supplier skipped edge preparation and left weld seams exposed after painting. Within two years, visible rust appeared, forcing sandblasting and recoating of every affected area. It disrupted operations for weeks.

Now, I make sure our QC team inspects and verifies every prep step—especially in areas where two protection systems overlap, like anchors or handrail connections. Choosing the right method and not cutting corners is the only way to ensure platform longevity, safe operation, and low lifecycle costs.

Redundancy means that if one member—or even one weld—fails, the load is smoothly transferred to another part of the structure. Proper load paths ensure that weight moves without bottlenecking or overloading any single member. This design principle keeps platforms standing not only in normal use but also under accidents or sudden overloads.

Top engineers always include continuous load paths and secondary bracing, often going beyond what building codes require. Platforms without redundancy are prone to total collapse if just one element is compromised; with redundancy, isolated failures become manageable repairs.

Years ago, I diagnosed a platform collapse at a remote site. Building code was met, but no redundancy had been added; a single column buckled due to an unexpected impact, and the whole structure gave way. In contrast, I have seen platforms with integrated bracing and backup supports last for decades with only minor repairs.

My recommendation: Always ask for designs that show load paths and backup support lines. Overengineering is an upfront investment, but it prevents catastrophic events and provides peace of mind in mission-critical facilities.

Generic steel platforms rarely match heavy equipment perfectly. Platforms must fit anchor points, align with vibration isolation pads, and provide the correct routing for cable trays, operator walkways, and escape routes. Custom design guarantees that every interface matches your operational needs, minimizing installation headaches and future modification costs.

The best suppliers insist on early involvement with both the platform designer and equipment providers. This allows for clear planning, fewer conflicts, and integrated safety features from the start.

Once, I supported a client who delayed custom design for a massive conveyor installation. They tried to adapt a standardized platform but ran into bolt misalignment, vibration issues, and unsafe access routes. Only after spending heavily on modifications did they see the value of tailored platforms.

These experiences reinforced for me that bringing suppliers in early for design collaboration saves time, money, and nights of stress. Never treat custom design as “extra”; it is essential for complex, heavy-load projects.

Quality control is not about checking boxes—it is the backbone of safe, lasting structural performance. Genuine QC means involving third-party inspectors, mapping every weld, measuring dry film thickness (DFT) of paint layers, and recording the torque on every key bolt. These records show accountability and build a chain of trust from fabrication to final delivery.

Top buyers know that “QC by word of mouth” is never enough. Lower-cost vendors sometimes skip internal documentation or limit inspection to save money. This puts your entire investment at risk, often only discovered after a failure happens.

I saw this firsthand when a global client accepted “inspect as you go” procedures and later found major welds completely skipped on a hidden interior brace. When third-party inspectors arrived, repairs required full platform shutdown and removal of heavy equipment.

Now, I encourage buyers to request—and review—every QC record before paying the final invoice. Open-book QC documentation not only guarantees safety but also streamlines compliance checks and makes future maintenance simple.

Steel platforms succeed by combining conservative engineering, certified materials, professional connections, robust coatings, and total QC transparency. Only integrated solutions offer lasting reliability and real peace of mind.