Pressure vessels sit on steel that must not fail. Heat, pressure, and quakes raise the stakes. I share my field-tested method to keep supports safe, fast, and cost-wise.

Steel support structures for pressure vessels carry operating, wind, seismic, thermal, and accidental loads into the foundation. I design for codes, corrosion, fabrication, and install. I balance safety, schedule, and total cost for petrochemical plants.

I know your schedule is tight and your risk is real. I keep this guide specific and practical. I show what to check, what to avoid, and how to win time and money. I also share moves that turned delays into early handovers. Stay with me, because each section answers a hard question you face today.

Are safety and compliance the first gate for vessel supports?

Paperwork does not stop leaks. A missed load case can. I do not bet the plant on lucky assumptions. I design for what can happen, not just what should happen.

Yes. Safety and compliance come first. I cover ASME Section VIII data, AISC 360 design, ASCE 7 wind and seismic, and ACI 318 anchors. I add accidental and erection loads. I lock welds, bolts, and inspection early.

Making supports “fail-safe,” not just “code-safe”

-

Loads and combinations

-

I gather vessel weight, contents, hydrotest, nozzle loads, and temperature cycles from the vessel datasheet and the process team.

-

I apply wind, seismic, snow (if any), blast or upset, and erection loads per ASCE 7 and owner specs. I build combinations for strength and serviceability.

-

Anchorage and foundations

-

I size baseplates, grout, and anchor rods per ACI 318, including tension, shear, prying, and concrete breakout. I check edge distances and embedment. I add sleeves or templates for tolerance.

-

I include fire and heat shields where needed near hot skirts. I protect anchors from corrosion with sleeves or coatings.

-

Joints and inspection

-

I specify full-penetration welds only where the load path needs it. I use partial-penetration or fillet welds with proper sizing elsewhere to control distortion and cost.

-

I use slip-critical bolting for seismic or dynamic joints. I define surface class for slip factor. I call out VT, MT, UT, and third-party witness points.

Example: A vendor once ignored seismic drift on a tall frame beside a column. I added X-bracing, slip-critical joints, and bigger anchors. The fix removed a retrofit and a shutdown risk.

|

Safety check

|

What I verify

|

|

Skirt or saddle interface

|

Contact width, local stress, temperature, and nozzle protection

|

|

Lateral drift

|

Nozzle movement limits under wind and quake

|

|

Stability

|

Uplift, sliding, and P-Delta effects

|

|

QC plan

|

Hold points, NDT scope, acceptance, and repair methods

|

Do schedule and delivery decide who wins the project?

A handoff gap can waste a week. A missing bolt can stop a crew. I remove weak links. I run one plan from design to lift.

Yes. Schedule and delivery decide wins. I use integrated design, buy, fabricate, and install. I release anchors early. I ship modules. I lock QA on day one. I protect the critical path.

Compressing time without cutting corners

-

Early release

-

I freeze interface data fast: vessel footprint, baseplate sizes, anchor patterns, and elevations. I release anchor bolts, templates, and plates in week one. The civil crew keeps moving.

-

Standard details and templates

-

I use a standard set of gussets, stiffeners, splices, and ladders. I preload the detail library. I reduce drawing time and shop setup time.

-

Parallel work and fast RFI

-

I run weekly 3D model reviews with the EPC team. I clear clashes and RFIs in 24–48 hours. I never wait for a perfect IFC to start shop-level details.

-

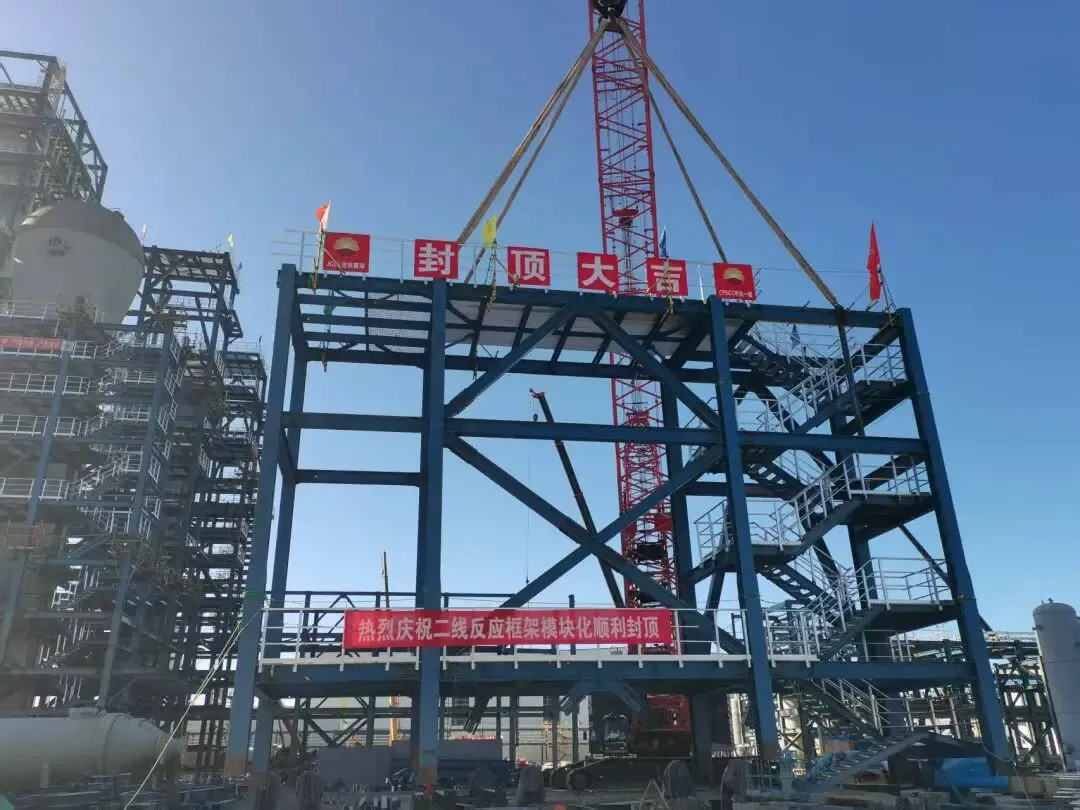

Modularization

-

I shop-assemble frames, platforms, and pipe shoes. I target 80–120 kN per lift where the site crane can handle it. I mark center-of-gravity. I match modules to road permit limits.

-

QA in the plan

-

I lock WPS/PQR, NDT, and paint DFT before the first cut. I align cure times with shipping windows. I plan holiday tests and bolt tensioning on the module stand.

-

Logistics

-

I book trucks early. I pack bolt kits by module with labeled bags. I include two spare anchors per baseplate and torque charts in each crate.

Result: I once delivered a vessel support line 40 days early. I used early anchor release, modular frames, and coat-cure during the vessel hydrotest window. The site cut a month from tie-in.

|

Time lever

|

Action

|

Typical gain

|

|

Anchor early release

|

Template issue in week one

|

7–10 days

|

|

Standard details

|

Library reuse

|

3–5 days

|

|

Modularization

|

Shop preassembly

|

5–12 days

|

|

QA front-loaded

|

No rework loops

|

3–7 days

|

Does corrosion protection decide lifetime cost more than price?

A low-price frame can rot fast. Acid gas, salt, and heat punish poor prep. I plan for the full life, not the bid day.

Yes. Corrosion drives lifetime cost. I match the system to the environment. I favor hot-dip galvanizing plus a topcoat in harsh zones. I define prep, DFT, tests, and warranty in plain terms.

Picking and proving the right protection

-

Environment classification

-

I check H2S, SO2, chlorides, temperature, wet-dry cycles, and washdowns. I map splash zones and CUI zones near hot vessels. I use ISO 12944 categories (C4/C5/Im2) as a guide.

-

System selection

-

I use HDG per ASTM A123 for broad defense. I target 85–120 µm zinc. I add a duplex topcoat (zinc-rich epoxy + fluoropolymer) for UV and chemicals. I use high-build novolac epoxy (400–600 µm) in immersion or spill trays. I use thermal spray aluminum for hot spots.

-

Design for coating life

-

I round edges to a 2 mm radius. I seal-weld crevices. I add vent and drain holes for HDG. I isolate dissimilar metals at anchors with sleeves or washers. I keep weep holes clear.

-

Execution and QA

-

I specify blast to SSPC-SP 10 / Sa 2.5. I state DFT ranges per coat. I require holiday testing in CUI and splash zones. I define field repair kits with zinc-rich primers and DTM topcoats. I document batch numbers.

Proof: I moved a client near an acid flare from single-coat epoxy to HDG plus fluoropolymer. Five-year maintenance dropped to near zero. The owner stopped annual touch-ups.

|

Zone

|

System

|

Target DFT

|

|

General yard

|

HDG only

|

85–120 µm

|

|

C5-M harsh

|

HDG + epoxy + fluoropolymer

|

250–320 µm total

|

|

Immersion/splash

|

Zinc primer + novolac epoxy

|

400–600 µm

|

|

Hot spots

|

Metalizing + seal coat

|

200–300 µm

|

Can advanced detailing solve odd shapes and crowded pipe racks?

Real sites are messy. Racks, ducts, and roads fight for space. A generic frame will not fit. I treat each support like a custom tool.

Yes. Advanced detailing solves odd shapes. I use hybrid members, smart clearances, and adjustability. I check all load cases. I give options with weight, cost, and install time.

Turning a tricky layout into a clean install

-

3D model and clearances

-

I import the vessel, nozzles, ladders, insulation, and nearby steel. I place rigging paths and crane envelopes. I set minimum clearances: 600 mm for access, 75 mm for insulation, and 25 mm for paint tolerance.

-

Structure choices

-

I use W-beams for girders. I use pipe columns where space is tight or fireproofing is heavy. I use collars and cap plates under saddles. I design for thermal growth with sliders or stops.

-

Limits and checks

-

I set drift limits to protect nozzles (often L/400 or 10 mm max at nozzle). I check resonance against process pulsation and compressor speeds. I model anchor stiffness and grout thickness.

-

Install tolerance

-

I slot baseplates in one axis ±6 mm. I use leveling nuts and 25–50 mm grout. I add survey targets on plates. I issue a shim plan and a grout sequence. I mark pick points and weights.

Case: A vessel had to straddle a culvert and a cable tray. I used pipe columns, a tapered girder, and a slider at one saddle. The crew set the frame in one lift. The vessel dropped in with no field grinding.

|

Design item

|

Typical target

|

|

Plumbness

|

H/1000 or better

|

|

Baseplate level

|

±1 mm over plate

|

|

Anchor projection

|

+2/−0 threads after nut

|

|

Drift at nozzle

|

≤10 mm under SLE

|

Is the lowest price the best value for pressure-vessel supports?

A low bid hides risk. Rework, delays, and weak QA cost more later. I do not chase the cheapest number. I protect total cost and schedule.

No. Lowest price is not best value. I qualify partners by capacity, QA, and field support. I demand third-party reports. I check welds, bolts, and traceability. I want a site-ready plan and aftercare.

Qualifying a partner and avoiding hidden costs

-

People and plant

-

I require a named project manager, planners, and QC. I review crane capacity, oven size, paint booth climate, and galvanizing bath size. I ask for similar jobs in the last 24 months and client contacts.

-

Welding and bolting quality

-

I review WPS/PQR per AWS D1.1. I check welder certs and continuity. I define NDT scope by joint criticality. I verify MTR traceability by heat number. I confirm bolt grades (A325/A490 or F3125) and sources. I check slip-critical surface class and lubrication.

-

Documentation and oversight

-

I require an ITP with hold points. I bring in a third-party lab for UT and coating DFT. I invite client witness. I close all NCRs before ship. I issue redline-as-built alignment.

-

Field support

-

I ask for a field engineer for first fit. I stock spare anchors, nuts, and shims. I provide torque charts, grout instructions, and touch-up kits. I commit to 24-hour response during lifts.

I also train client teams on support basics. That training cuts change orders and fit-up delays. It builds trust. It prevents surprises you cannot budget.

|

Risk area

|

Proof I ask for

|

|

Weld quality

|

UT/MT reports, repair logs

|

|

Bolt performance

|

Tension tests, lot certs

|

|

Coating durability

|

DFT records, holiday tests

|

|

Schedule control

|

Look-ahead, staffing plan

|

Conclusion

Safe, fast, durable supports come from full-load design, integrated delivery, right coatings, precise detailing, and strong vendor QA. I use this playbook to de-risk your job end to end.