Time:2025-12-17 08:15:47 Source:Sanjian Meichen Steel Structure

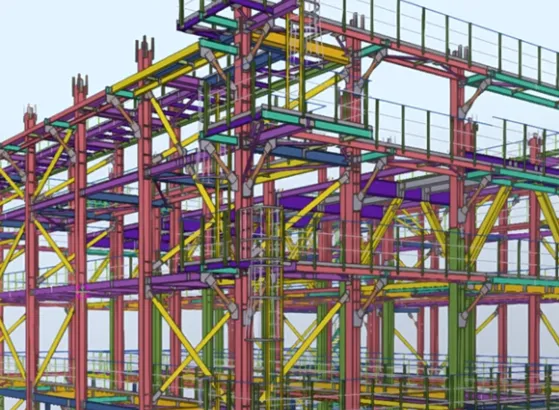

Refinery heavy equipment support frames can fail in unexpected ways. In my experience, engineers routinely underestimate the hidden loads a frame may see over decades of use. I now believe that successful design comes from getting honest, detailed load data—from equipment manufacturers, operation teams, and installation partners—and questioning every assumption that sounds “standard.” The best frames build in surplus capacity and flexibility for future change.

Support frames for refinery heavy equipment are most at risk not from obvious static weights, but from underestimated “invisible” loads—whether it’s a maintenance crane, accidental surge, added cable tray, or distributor cleaning cycle. Reliable, long-life frames demand a forensic exploration of every real and possible load, planned with discipline and validated by critical questioning.

I want to highlight the overlooked load types and practical solutions that transformed my approach to heavy equipment frame projects. Good design is not about overbuilding for what you see on day one, but predicting what decades of operation, maintenance, upgrades, and accidental events will demand. Only with a mindset of “planned caution” can an EPC team and plant owner achieve peace of mind on safety and cost.

Many engineers look at heavy equipment support and picture only the vessel’s weight plus attached platforms, stairs, and piping. In reality, things like cranes, scaffolding, cable trays, test stands, and even temporary repairs all place vertical loads that, if missed, lead to failure or on-site delays.

Getting vertical loads right is about more than just weighing the main equipment. I’ve seen projects where a frame design “passed” all calculations—only to buckle under the weight of a maintenance crane brought in during shutdown, or after a cable tray was added without warning.

Some common oversights include:

Removable insulation weight

Ladders with tools left during outage

Temporary loads from scaffolding and personnel during inspection

In one refinery, missed allowance for a portable hydraulic jack nearly caused a dropped vessel during maintenance. Another example is installation surprises—frames stressed by misaligned lifts or accidental use of heavier-than-expected rigging gear.

For every frame, I now ask the procurement and construction team for a list of all expected and possible “vertical events”—including abnormal maintenance, emergency equipment placement, or storage. I insist on written numbers from specialists in instrumentation and operations.

If the load list feels too short or makes too many assumptions, it’s a warning sign. My spreadsheet for vertical loads always includes a “temporary load” line, and I typically apply a 10–20% redundancy (my personal “worry buffer”) for the unexpected. The few hours spent collecting this data upfront have saved weeks of remediation and significant cost later.

| Vertical Load Type | Typical Examples | Hidden Risks When Missed |

|---|---|---|

| Main equipment | Vessel, reactor, tower | Static overload, foundation failure |

| Platforms & handrails | Catwalks, stairs, inspection areas | Deflection, trip hazards |

| Piping + insulation | Process, utility lines, insulation | Sag, joint rupture |

| Maintenance crane | Chain hoists, traveling cranes | Frame collapse during service |

| Scaffolding / jacks | Shutdown lifts, test stands | Installation-time buckling |

| Cable tray / duct | Power, control, signal racks | Local punch-through, support tear-out |

| Temporary storage | Repair parts, tools, spare motors | Overload during outage |

Support frames for dynamic equipment face stress far higher than anything seen in static cases. Pumps, compressors, and motors transfer vibrations, sudden shocks from startup/stops, and long-term cyclical forces that cause fatigue or dangerous resonance.

Dynamic loads are one of the most underestimated hazards for refinery frames. I’ll never forget one incident: a brand-new compressor, statically supported, created constant noise and mounting bolt loosening. The root cause was a lack of modal analysis—the motor’s vibration matched the frame’s natural frequency.

It took months of trial fixes before the client agreed to engage a vibration specialist and add bracing.

Since then, I insist every critical equipment supplier (pumps, compressors, fans) provide a full vibration baseline, including:

Amplitude

Frequency

Operating regime

Expected surges and stops

I also analyze maximum shock loads during hard start and emergency stop using OEM test values. There is no shortcut: all supports for dynamic equipment must undergo finite element dynamic or modal analysis, not just static checks.

Sometimes static beams are simply not enough—you may need heavier sections, shorter spans, or special damping pads.

| Dynamic Load Source | Real-World Effects | Necessary Actions |

| Equipment rotation | Resonance, noise, fatigue cracks | Dynamic/modal analysis, damping system |

| Start/stop shock | Instantaneous overload or movement | Include OEM maximum shock load |

| Cyclical operation | Bolt loosening, joint failure | Fatigue checks, bolted connection review |

| Misalignment | Unbalanced cyclic load | Require as-installed alignment data |

It’s easy to design a frame only for “normal” plant operation. But rare process states—like vessels filled for testing, charging, or emergency flushing—can instantly add massive loads.

One project involved a tall reactor designed for normal process weight. During catalyst loading and fluid charging, the structure was pushed to the edge of collapse. The lesson was clear: never ignore temporary or rare fill conditions.

Always confirm with the process engineering team:

Cleaning and flushing states

Test fill conditions

Emergency or upset operations

Accident loads matter just as much. Modern refineries increasingly require frames to resist:

Local blast pressure

Fire-induced heat reducing steel strength

Emergency depressurization surges

I’ve seen frames tear open during fire events simply because no thermal expansion path or fire protection was designed in. Low-cost solutions at design stage—like removable panels, reinforcement brackets, or sacrificial elements—can prevent millions in damage.

| Non-Normal Load | Typical Event | Protective Steps Needed |

| Full charge weight | Cleaning or fill test | Confirm vessel capacity and update loads |

| Accidental fire | Pipe leak and ignition | Thermal bands, expansion paths |

| Blast / overpressure | Gas release, explosion | Anti-blast brackets, reinforced joints |

| Emergency overflow | Operator error or upset | Temporary overflow paths, local stiffening |

| Sudden depressurization | Valve trip, process upset | Shock-resistant bracing elements |

Frames designed for “average” environments often fail under real site conditions.

On one Gulf Coast project, a frame sized for “typical” U.S. wind loads had to be redesigned when local data showed wind speeds 30% higher. Seismic risks are even more sensitive—soil class, fault proximity, and equipment response all matter.

My current rules:

Seismic and wind analysis must use site survey data, not code averages

Seismic checks should be response-spectrum based, with nonlinear verification

Wind checks must consider construction-stage and future equipment additions

Temperature effects are often ignored. Without sliding bearings or expansion allowances, hot-cold cycles cause cracking and misalignment. I now always specify expansion slots near hot process equipment.

| Environmental Load | Real-World Drivers | What to Demand |

| Seismic | Location, soil, equipment response | Site-specific, spectrum-based analysis |

| Wind | Height, layout, gust patterns | Local wind records, construction-phase checks |

| Temperature | Thermal cycles, solar exposure | Expansion slots, sliding bearings |

| Rain / Ice | Local climate | Drainage, ponding checks |

Refinery frames rarely support only one system. Cable trays, pipe racks, platforms, hoists, and workers often occupy the same structure simultaneously.

During shutdowns, crews stack tools, scaffolds, and materials on walkways never designed for storage. The danger lies not just in total weight, but local load concentration.

My approach now includes:

Plant walkdowns to observe real behavior

Interviews with maintenance crews

Adding excess live load, often 1.5× code minimum, at key locations

| Overlapping System | Example Loads | What’s Missed / Needed |

| Pipe rack + cable tray | Bundled cables | Combined modeling of tray and cable |

| Workers + toolboxes | 4–10 people plus tools | Full occupancy + storage allowance |

| Maintenance platforms | Spare valves, parts | Hoist path and movement loads |

| Temporary loads | Carts, scaffolding | 150% live load at critical zones |

Refineries evolve continuously. Frames designed to minimum specification make every future change risky and expensive.

Modern support frames should plan for the unknown, especially in units likely to expand. I now focus on:

Bolted rather than welded connections at critical points

Stub plates and sleeves for future bracing

Reserved space for added trays or platforms

Working directly with O&M teams reveals where real modifications usually happen. Allowing 10–30% extra load capacity at key locations often costs little today but saves enormous retrofit cost later.

| Future Change Type | Real Example | Design for Flexibility |

| Extra equipment / trays | New controls, motors | Stub plates, modular bolt patterns |

| Process upsize | Larger pumps, higher flow | Oversized holes, predrilled reinforcement |

| O&M workarounds | Temporary jacks, rework | Strong continuous girders |

| Safety code changes | Guardrail upgrades | Clamp-on points, thicker slabs |

Every truly safe and cost-effective refinery equipment support frame is the result of relentless attention to both visible and hidden loads, realistic planning for real operation, and deliberately built-in flexibility for the future. Designing with planned caution protects not just steel—but uptime, safety, and long-term project value.