Time:2025-11-12 06:28:39 Source:Sanjian Meichen Steel Structure

Steel structures form the backbone of modern industrial buildings, warehouses, bridges, and large-span roofs. These structures are designed to withstand various loads and environmental conditions while ensuring long-term durability and safety. In this comprehensive guide, we will explore the essential components of steel structures, providing detailed insights into the primary load-bearing elements, secondary support members, connections, and protective materials. This will equip you with the knowledge to understand how each component contributes to the overall performance and stability of a steel building.

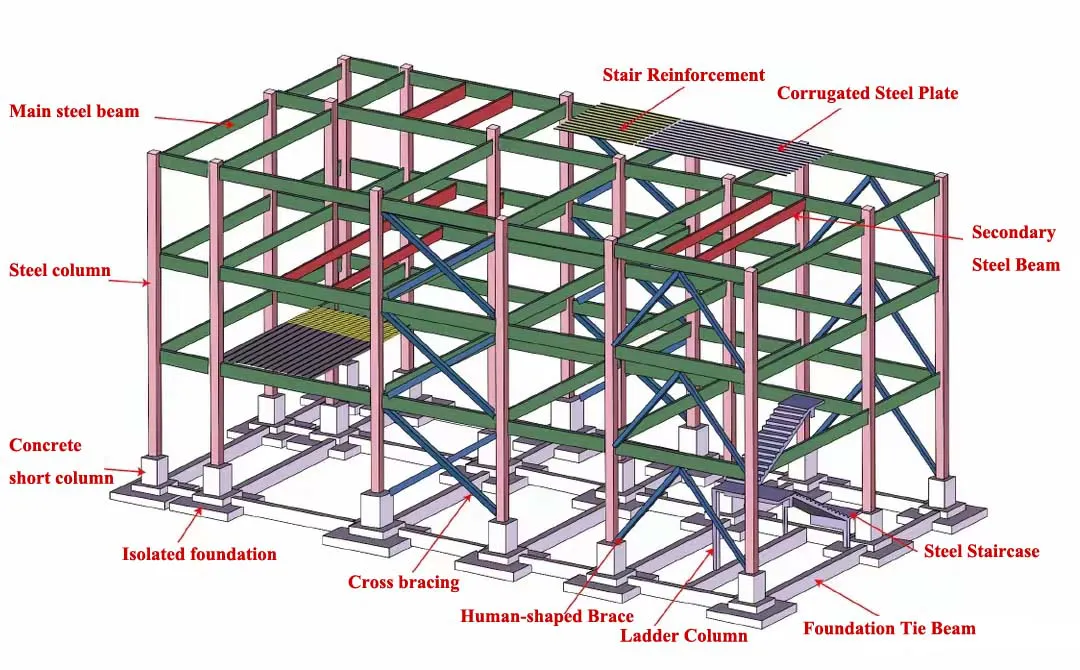

The main load-bearing components are critical in supporting the structure's weight and ensuring stability. These components are designed to carry both vertical and horizontal loads and distribute them effectively to the foundation.

Function:

Steel columns are vertical structural elements that transfer the load from the beams and roof to the foundation, playing a pivotal role in the building's stability. They are crucial for bearing the structure's vertical load.

Types:

H-Beam Columns: Popular in large-span steel structures due to their excellent load-bearing capacity and stability.

Box Section Columns: Used for buildings that require higher stability and enhanced seismic resistance.

Built-Up Columns: Constructed from welded steel plates, designed to support heavy loads when standard columns are insufficient.

Requirements:

Steel columns must meet rigorous standards for strength, stability, and rigidity to ensure the overall integrity of the building. Proper material selection and precise engineering are essential.

Function:

Steel beams are horizontal members that support loads from floors, roofs, and other building components, transferring the forces to the columns.

Types:

I-Beams: The most commonly used type, known for their superior bending resistance and load capacity.

H-Beams: Feature wider flanges, providing better load distribution and increased stability.

Plate Girders: Heavy-duty beams used for long spans and high-load applications, fabricated from welded plates for added strength.

Requirements:

Beams must be designed to withstand bending and shear forces, ensuring effective load distribution and minimal deflection under heavy loads.

Function:

Steel trusses and grid frames are used in large-span roofs and bridges. These interconnected structures efficiently transfer loads while maintaining a lightweight, stable form.

Types:

Triangular Trusses: Commonly used in roof structures for large spans, offering excellent load distribution without requiring additional columns.

Flat Grid Frames: Ideal for applications requiring wide coverage, such as in warehouses and large commercial buildings.

Support components are essential for enhancing the structure’s lateral stability and ensuring the transfer of lateral forces such as wind and seismic activity.

Function:

Bracing between columns adds lateral stability to the structure, preventing deformation under lateral loads like wind or earthquakes. Proper bracing ensures the structural integrity is maintained under dynamic loads.

Types:

Steel Bracing: Provides support against lateral forces, commonly used in large structures.

Circular Steel Bracing: Suitable for high-strength applications, offering flexibility without compromising stability.

Function:

Roof bracing prevents roof deformation under external loads such as snow, wind, or seismic activity. It ensures that the roof remains stable and rigid during pressure fluctuations.

Types:

Horizontal Bracing: Helps maintain lateral stability and prevents roof displacement.

Vertical Bracing: Provides additional vertical support to stabilize the roof structure under pressure.

Function:

Tie rods connect roof trusses or purlins to the main steel framework, preventing distortion and ensuring overall structural stability. They help maintain the integrity of the steel frame during dynamic forces.

Types:

Round Steel Rods: Typically used in roof trusses to resist tension forces and maintain structural alignment.

Angle Steel Tie Rods: Strong, angled connections that secure various steel elements, ensuring stability in both horizontal and vertical directions.

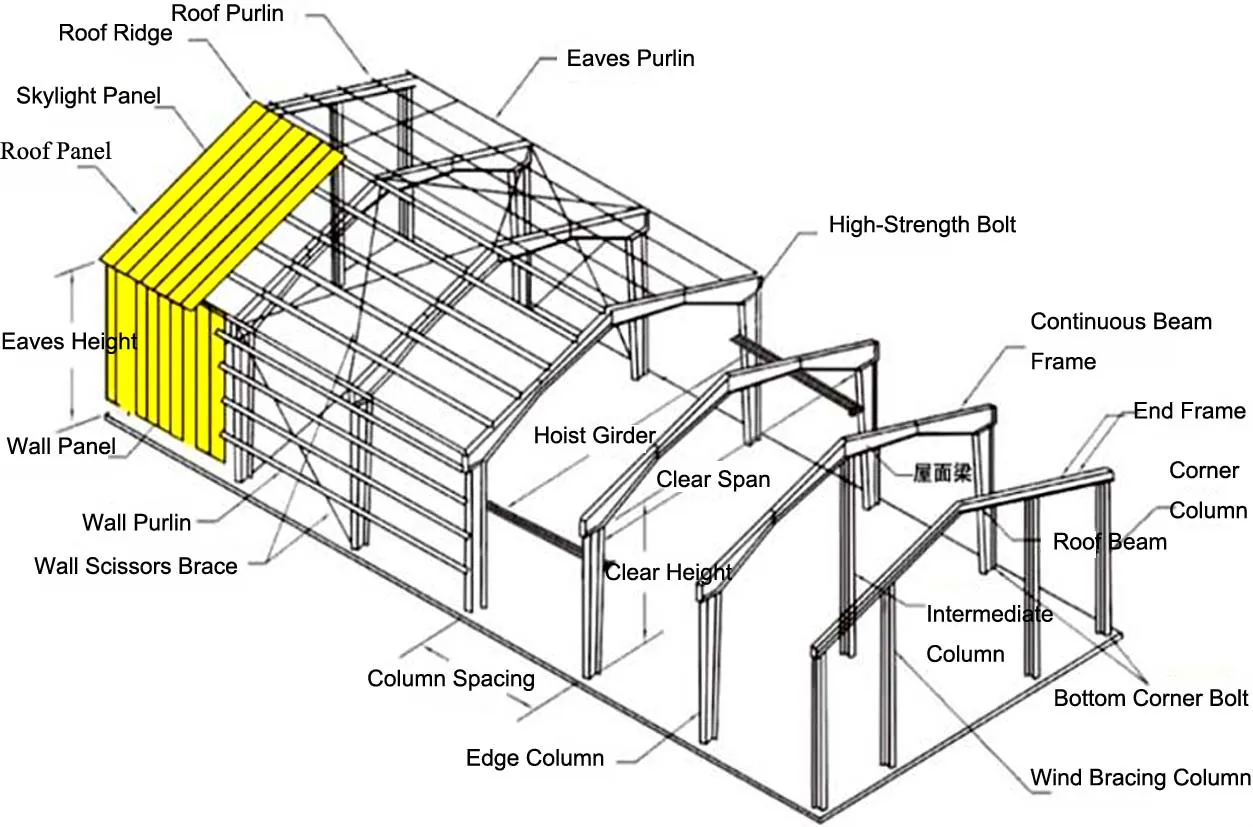

These components support the primary load-bearing elements and help distribute loads across the structure, ensuring uniform stress distribution.

Function:

Purlins are horizontal members that span across the roof structure, supporting the roofing panels and transferring loads to the primary beams.

Types:

C-Section Purlins: The most commonly used type due to their cost-effectiveness and efficient load distribution.

Z-Section Purlins: Ideal for larger spans or more complex roof designs, offering enhanced load-bearing capacity.

Function:

Similar to purlins, wall girts are horizontal members placed along the walls to support the building's cladding.

Types:

C-Section Girts: Suitable for lightweight applications and easy to install.

Z-Section Girts: Designed for heavier-duty applications, providing higher load-bearing capacity.

Function:

Corner braces connect purlins or girts to the main steel frame, preventing structural distortion and ensuring rigidity.

Types:

Angle Braces: Commonly used in corner connections to enhance stability and prevent buckling under load.

Connections are the key elements that link individual steel members together, ensuring the structure's integrity and strength. These components must be robust to transfer forces effectively between connected members.

Function:

Bolted connections are used extensively in steel construction due to their strength, ease of assembly, and flexibility for adjustments.

Types:

High-Strength Friction Bolts: Used in critical connections that require high strength and stability.

Bearing Bolts: Primarily used to transfer loads through bearing contact, providing secure connections in non-critical areas.

Function:

Welding is a permanent joining method used to connect steel members, ensuring a strong and continuous bond.

Types:

Butt Welds: Used to join the ends of two steel members, ensuring a seamless and robust connection.

Fillet Welds: Common in connecting angled components such as beams to columns, offering flexibility and strength.

Function:

End plates are used in beam-column connections, welded to the steel beam and column, with bolts transferring the internal forces from the beam to the column.

Steel structures are vulnerable to environmental factors such as corrosion, temperature fluctuations, and weathering. Protective components ensure the longevity and performance of the structure by mitigating these risks.

Function:

Roof and wall panels protect the building from environmental elements, providing insulation, weather resistance, and aesthetic appeal.

Types:

Corrugated Steel Sheets: Widely used due to their durability, cost-effectiveness, and resistance to external elements.

Color Coated Sheets: Provide enhanced corrosion resistance and offer an aesthetically pleasing finish.

Function:

Skylight panels allow natural light into the building, reducing reliance on artificial lighting and improving energy efficiency.

Function:

Gutters collect and direct rainwater from the roof to drainage systems, preventing water damage to the building's exterior and foundation.

Steel structure components play a vital role in ensuring the strength, stability, and longevity of modern buildings. From the primary load-bearing elements like columns and beams to the secondary components such as purlins and bracing, each element is carefully designed to handle specific loads and environmental challenges. Understanding these components and how they interact is crucial for engineers, architects, and construction professionals to design and build safe, efficient, and cost-effective steel structures.

By selecting the right materials, using advanced design techniques, and ensuring proper installation, steel structures can provide exceptional performance, durability, and value across a wide range of applications, from industrial facilities to commercial buildings.