Time:2026-01-23 02:38:41 Source:Sanjian Meichen Steel Structure

In today’s highly competitive industrial landscape, efficiency, safety, and long-term cost-effectiveness are no longer optional—they are essential for sustainable growth. Whether a company is planning to expand, relocate, or modernize production facilities, investing in a customized steel structure factory has become the smart choice. Unlike traditional construction methods, steel structures offer rapid build timelines, flexible layouts, superior strength, and long-lasting durability, making them ideal for industries including manufacturing, logistics, warehousing, automotive, and food processing.

A well-designed steel structure factory isn’t just a building—it’s a strategic investment that directly impacts workflow efficiency, operational safety, and return on investment.

1. Designs Tailored to Your Operational Needs

Every business operates differently, and standardized buildings often fail to optimize production flow, material handling, or storage efficiency. Customized steel structures allow engineers to design layouts around your specific workflow, including:

Ceiling heights for large machinery or automated systems

Column spacing to maximize usable floor space

Loading and unloading areas for trucks and logistics

Mezzanines or multi-level storage for inventory optimization

Integrated office or control rooms to monitor production in real time

By aligning the building design with operational processes, businesses can minimize bottlenecks, improve material movement, and enhance overall productivity.

2. Fast Construction Minimizes Downtime

Steel structures are renowned for their speed of construction. Pre-fabricated components can be manufactured off-site under controlled conditions, then transported and quickly assembled on-site, reducing construction timelines from months to weeks. This approach is particularly valuable for:

Businesses scaling operations

Relocating or upgrading production lines

Launching new facilities with minimal disruption

A faster build means companies can start production sooner, meet deadlines, and avoid lost revenue from prolonged downtime.

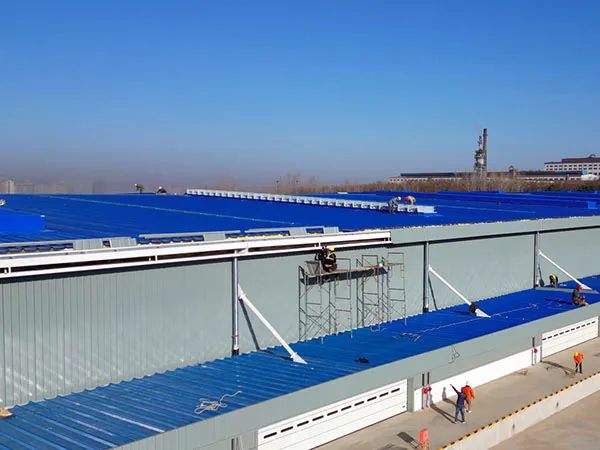

3. Durable, Safe, and Weather-Resistant

High-quality steel is naturally resistant to:

Fire and corrosion

Pests such as termites

Extreme weather conditions including heavy snow, strong winds, or earthquakes

Customized designs can further incorporate:

Earthquake-resistant frames

Reinforced roofing and cladding

Energy-efficient insulation

Advanced ventilation and lighting systems

This ensures a safe working environment for employees and protects sensitive machinery, minimizing the risk of costly downtime or accidents.

4. Cost-Effective Over the Long Term

Although initial construction costs may be higher than conventional concrete or brick buildings, steel structures offer significant long-term savings:

Reduced maintenance and repair costs

Longer building lifespan (often exceeding 50 years)

Flexible expansion options without major structural changes

Improved energy efficiency, reducing utility costs

For businesses with long-term growth plans, a customized steel structure is both a practical and strategic investment.

A professional steel structure service ensures every project is handled efficiently, from planning to post-construction support:

Site Analysis & Planning: Assess land topography, soil conditions, environmental constraints, and operational requirements to create the most efficient layout.

3D Modeling & Simulation: Visualize your facility in detail, detect potential issues before construction, and refine the workflow design.

Structural Engineering: Ensure compliance with local building codes, safety standards, and industry-specific regulations.

Fabrication & Installation Support: Coordinate off-site manufacturing, logistics, and on-site assembly to streamline the construction process.

Post-Construction Consultation: Provide ongoing guidance on maintenance, upgrades, and future expansion, helping businesses maximize the value of their investment.

Customized steel structures are already widely used across industries:

Automotive plants: Support heavy machinery and assembly lines while allowing for future expansion.

Logistics and warehousing: Maximize storage capacity with mezzanine systems and optimized layouts for forklift movement.

Food processing: Provide hygienic, easy-to-clean environments with proper ventilation and insulation.

Electronics manufacturing: Protect sensitive equipment with climate-controlled spaces and reinforced flooring.

These examples demonstrate how industry-specific customization enhances operational efficiency, safety, and productivity.

A customized steel structure factory is more than a building—it’s a long-term strategic asset. By working with experienced engineers and design professionals, companies can ensure that their facility:

Matches their unique workflow

Provides a safe, durable environment

Minimizes downtime during construction

Reduces long-term operational costs

For businesses ready to expand, relocate, or modernize, exploring custom steel structure solutions is the key to future-proofing operations, improving productivity, and staying competitive in an evolving market.

Invest in a facility that works as hard as your team—because a well-designed factory is the foundation of sustainable growth.