Time:2025-11-07 02:40:10 Source:Sanjian Meichen Steel Structure

Steel structure detailing plays a crucial role in modern construction, especially for large-scale projects that demand precision, efficiency, and longevity. This process involves refining a structural design to a level that ensures all components work seamlessly together. With the integration of BIM technology (Building Information Modeling), steel detailing not only supports the creation of accurate construction documents but also enhances collaboration between teams, ensuring timely and cost-efficient project delivery.

MEICHEN STEEL STRUCTURE, a leading steel structure provider with over 25 years of industry experience, understands the importance of precise detailing and the role it plays in the successful completion of projects. By utilizing cutting-edge tools like Tekla Structures, MEICHEN ensures that every project is designed to meet the highest standards of quality, safety, and efficiency.

In this article, we explore the crucial steps involved in steel structure detailing, the tools used, and the numerous benefits this process brings to construction projects. We will also highlight how using advanced software like Tekla Structures can help improve your design and construction process.

Steel structures are the backbone of many modern buildings, from high-rise offices to industrial facilities. Steel’s strength, flexibility, and ability to withstand extreme conditions make it an ideal material for supporting heavy loads and providing robust frameworks for various applications.

Steel detailing helps transform an architect’s conceptual design into a set of precise, actionable construction plans. Detailed steel designs are essential for ensuring that all components are fabricated and installed according to specifications, avoiding costly mistakes and delays during the construction phase.

MEICHEN STEEL STRUCTURE ensures that every steel structure is designed with precision and attention to detail. By leveraging its decades of expertise, MEICHEN STEEL STRUCTUREprovides optimized designs that reduce material waste and accelerate construction timelines, all while maintaining the highest quality standards.

Example: A commercial warehouse project required detailed steel design to ensure it could withstand the loads from heavy machinery. Thanks to the effective detailing by MEICHEN STEEL STRUCTURE, the project was completed ahead of schedule and under budget, thanks to reduced material waste and minimized on-site changes.

Client Concern: "How can I be sure my steel structures will be accurate and stable?"

Answer: Steel structure detailing ensures that the materials are cut, welded, and assembled according to exact specifications. Using advanced tools like Tekla Structures, MEICHEN STEEL STRUCTURE guarantees precision and faster construction with minimal error.

The steel structure detailing process includes several stages, each aimed at ensuring the accuracy, safety, and efficiency of the final structure. These steps are essential to converting initial designs into executable plans that contractors can rely on for successful construction.

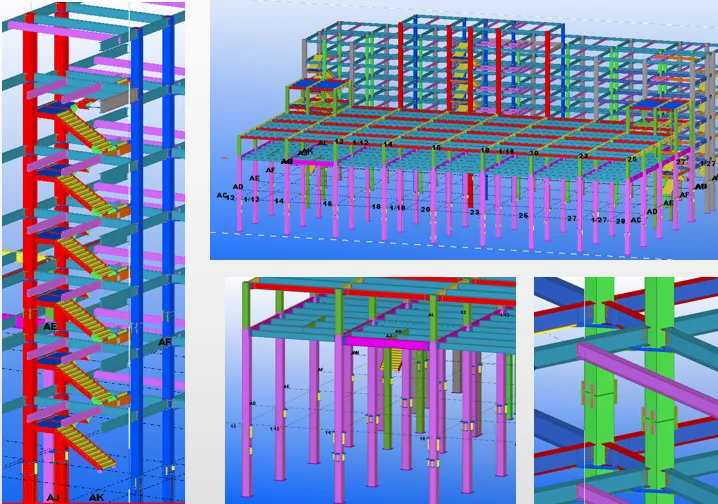

Steel structure detailing begins with the creation of a 3D model that includes every structural component. The model serves as the foundation for the entire design, detailing everything from beams and columns to joints and connections.

Tekla Structures: This industry-leading software allows for the creation of detailed 3D models that represent every aspect of the steel structure. With MEICHEN STEEL STRUCTURE using Tekla Structures, clients can expect highly accurate and well-organized models that make construction straightforward.

The basic Tekla modeling workflow involves first setting up the grid axes and establishing or selecting a working view. Next, an initial layout is generated by creating the main and secondary members, followed by adding nodes and detailing components. Once the model is structured, numbering is executed to organize the elements. The layout can then be modified as needed, after which component and part drawings are generated. Finally, reports are produced, and the model can be exported as CAD drawings or PDF files for documentation and sharing.

Once the model is created, the design is optimized. This includes analyzing the load distribution, ensuring that the weight of the structure is efficiently supported. The optimization process might involve adjusting the size of beams or columns, changing the type of steel used, or repositioning certain components to improve efficiency and reduce costs.

Client Insight: "Can I reduce material costs without compromising quality?"

Answer: Yes, optimization through detailed design can help reduce material waste. MEICHEN STEEL STRUCTURE’s experienced engineers refine designs to minimize unnecessary material use, reducing costs while maintaining structural integrity.

Once the structure has been optimized, the final step in the detailing process is the generation of detailed construction drawings. These drawings include specific dimensions, joint details, and material specifications necessary for the construction team to begin their work.

Construction Drawings Include:

Detailed assembly drawings of steel components

Connection details for welding, bolting, and other joining methods

Fabrication drawings to guide the manufacturing process

Bill of materials (BOM) listing every component needed for the project

MEICHEN STEEL STRUCTURE guarantees that every project is supported by comprehensive and clear construction drawings, ensuring that the construction team has everything needed for accurate execution.

The use of Tekla Structures is instrumental in the modern steel structure detailing process. This advanced software provides a comprehensive solution for structural engineering and detailing, allowing design teams to create accurate 3D models and generate detailed construction documents. When combined with BIM technology, Tekla Structures ensures that all stakeholders—from architects to contractors—are working from the same data, reducing errors and improving project coordination.

MEICHEN STEEL STRUCTURE uses Tekla Structures for all of its steel detailing projects, providing several advantages:

Comprehensive 3D Modeling: Create highly detailed 3D models that include all aspects of the steel structure, from framing to connections.

Seamless Collaboration: Allow multiple team members to work simultaneously on the same model, ensuring a cohesive design without conflicting revisions.

Automatic Drawing Generation: Automatically generate construction drawings from the 3D model, significantly speeding up the process and reducing the chance of manual errors.

Material Management: Keep track of all materials and components, ensuring that no parts are overlooked and that quantities are accurate.

BIM allows for real-time collaboration between all stakeholders, ensuring that every change made in the design is instantly reflected across all documents. This reduces the chance of discrepancies and helps streamline communication, making the construction process more efficient and predictable.

Benefit: Real-time updates prevent costly mistakes and ensure that everyone involved in the project is working with the most current design.

Effective steel structure detailing isn't just about creating a 3D model; it’s also about ensuring that every component is manufactured, delivered, and installed with the highest level of precision. To maintain quality throughout the process, there are several best practices to follow:

Using standardized procedures ensures that every design document is consistent and meets the required codes and standards. This also makes it easier to review designs and ensure that they adhere to local building regulations.

One of the most critical aspects of steel detailing is clear and frequent communication between the design team, fabricators, and construction crews. Regular progress meetings, design reviews, and model checking should be scheduled to address any issues early in the process.

Before construction begins, every steel component should undergo a thorough inspection to ensure that all drawings and specifications are correct. Regular quality audits and checks at each stage of production help maintain the highest standards.

Steel structure detailing has been used successfully in a wide range of projects, demonstrating its ability to enhance project efficiency, reduce costs, and improve overall outcomes. Let’s take a look at a couple of examples:

A cold storage facility required a steel structure that could support heavy refrigeration units and large shelving systems. By using Tekla Structures, the team was able to design an optimized structure that reduced material costs and improved energy efficiency. The project was completed ahead of schedule due to the accuracy of the detailed plans.

MEICHEN STEEL STRUCTURE was instrumental in optimizing this project, ensuring that the steel structure was not only efficient but also cost-effective, reducing unnecessary material use.

A large office building required a steel frame that could support high loads across multiple stories. The team used detailed 3D modeling and BIM integration to ensure that the building’s frame would distribute these loads evenly. This allowed for quick fabrication and installation, meeting both time and budget goals.

Steel structure detailing is a critical part of the construction process, ensuring that all elements of a project come together smoothly and efficiently. By using advanced tools like Tekla Structures and leveraging BIM technology, construction teams can improve precision, reduce costs, and streamline communication. This results in faster project completion, higher quality standards, and fewer costly mistakes.

At MEICHEN STEEL STRUCTURE, we specialize in providing high-quality steel structure solutions for large-scale projects, ensuring the success of every endeavor. Contact us today for a consultation on how we can help with your steel structure detailing needs and improve the efficiency of your next project.