When procuring large-span steel structures, it is crucial to optimize both shipping costs and production costs to ensure that the overall expenditure is within budget while maintaining the quality and durability of the structures. This guide will explore various strategies to achieve cost efficiency, including selecting cost-effective materials, negotiating better prices with suppliers, reducing installation costs, and managing the complexity of designing custom steel structures.

What Are the Most Cost-Effective Materials for Large-Span Steel Structures?

Selecting the right materials is a key factor in reducing both production and shipping costs for large-span steel structures. Different materials have varying costs, performance characteristics, and suitability depending on the project requirements.

1. Carbon Steel (Low-Carbon Steel)

Carbon steel is the most commonly used material in steel structures due to its affordability and good performance in structural applications.

-

Advantages:

-

Low cost: Carbon steel is widely available and typically cheaper than alloyed or high-strength steels.

-

Good structural performance: High strength-to-weight ratio makes it ideal for large-span structures.

-

Disadvantages:

|

Material

|

Strength

|

Cost

|

Corrosion Resistance

|

Common Applications

|

|

Carbon Steel

|

High

|

Low

|

Low

|

General steel structures, warehouses

|

|

High-Strength Steel

|

Very High

|

Medium

|

Medium

|

Bridges, heavy-load structures

|

2. High-Strength Low-Alloy Steel (HSLA)

HSLA steel provides an optimal balance of strength and weight reduction, making it suitable for structures that require high load-bearing capacity with less material weight.

-

Advantages:

-

Lightweight but strong: Allows for more efficient use of material, reducing overall weight.

-

Better performance: It offers greater resistance to corrosion than carbon steel.

-

Disadvantages:

3. Galvanized Steel

Galvanized steel is coated with zinc to provide enhanced corrosion resistance, ideal for outdoor and high-humidity environments.

-

Advantages:

-

Longer service life: Due to its corrosion resistance, it has a longer lifespan, reducing long-term maintenance costs.

-

Low maintenance: Requires minimal upkeep after installation.

-

Disadvantages:

4. High-Strength Steel

High-strength steel is used when very high load-bearing capacity is required. This material is often used in projects such as high-rise buildings and heavy-duty industrial structures.

-

Advantages:

-

Disadvantages:

|

Material

|

Strength

|

Cost

|

Common Applications

|

|

High-Strength Steel

|

Very High

|

High

|

High-rise buildings, industrial structures

|

|

Galvanized Steel

|

Medium-High

|

Medium

|

Outdoor structures, coastal buildings

|

How Can I Negotiate Better Prices with Suppliers?

Negotiating with suppliers is a critical step in reducing the overall cost of purchasing steel structures. Effective negotiation can lead to better pricing, favorable payment terms, and additional cost-saving measures.

1. Bulk Purchase Discounts

The most straightforward way to reduce unit price is to purchase materials in bulk. Suppliers often offer discounts on large orders, which can significantly reduce overall costs.

-

Tip: If your project requires a large number of steel components, negotiate with the supplier to secure a bulk discount based on the order volume. Larger orders provide stability to the supplier, making them more likely to offer better pricing.

2. Long-Term Partnership

Establishing a long-term relationship with suppliers often leads to better pricing and service. Suppliers are usually willing to offer favorable terms to long-term partners as it guarantees future business.

3. Payment Terms Negotiation

The terms of payment can impact the final cost of the order. Suppliers might offer better prices in exchange for favorable payment conditions.

4. Competitive Bidding

Request quotes from multiple suppliers to compare prices. Having multiple competitive quotes allows you to pressure suppliers to lower their prices to win your business.

5. Market Knowledge

Being informed about current market prices, including steel price fluctuations, can give you leverage when negotiating.

|

Negotiation Tip

|

Benefit

|

Example

|

|

Bulk Purchase Discounts

|

Lower unit cost for larger orders

|

10-20% discount on large orders

|

|

Long-Term Partnership

|

Stable pricing and priority service

|

Yearly contract for steel supply

|

|

Payment Terms Negotiation

|

Reduced upfront costs and favorable terms

|

Early payment discount or installment plan

|

|

Competitive Bidding

|

Lower overall costs from supplier competition

|

Obtain competitive quotes from 3+ suppliers

|

|

Market Knowledge

|

Leverage market trends for better pricing

|

Purchase when steel prices are low

|

How Can I Reduce Installation Costs for Steel Structures?

Reducing installation costs is equally important as reducing material and production costs. Optimizing the installation process can significantly decrease the overall cost of the steel structure project.

1. Prefabrication and Modular Design

Using prefabricated components reduces the amount of work needed on-site, thus cutting down on labor and installation time. Prefabrication allows for higher precision and fewer errors during assembly.

2. Optimized Workforce and Equipment

Efficient use of labor and equipment can help reduce installation time and costs. Using advanced machinery like cranes, lifts, and automated systems can streamline the process.

3. Site Preparation

Proper site preparation before installation can eliminate delays and minimize the need for adjustments during the actual installation. Accurate measurements and proper foundation work are essential.

4. Schedule Management

Proper scheduling of tasks and sequencing ensures that all steps in the installation process are executed efficiently.

|

Installation Tip

|

Benefit

|

Example

|

|

Prefabrication and Modular Design

|

Reduced on-site labor and installation time

|

Prefabricated steel beams for faster assembly

|

|

Optimized Workforce and Equipment

|

Lower labor and equipment costs

|

Use of cranes for quick lifting of heavy components

|

|

Site Preparation

|

Reduced delays and rework

|

Accurate site measurements for easy installation

|

|

Schedule Management

|

On-time delivery and reduced labor costs

|

Detailed timeline to prevent project delays

|

How Do I Manage the Complexity of Designing Custom Steel Structures for Large Projects?

Designing custom steel structures for large projects involves a high level of complexity. Ensuring that the design meets all functional, aesthetic, and structural requirements is essential for project success.

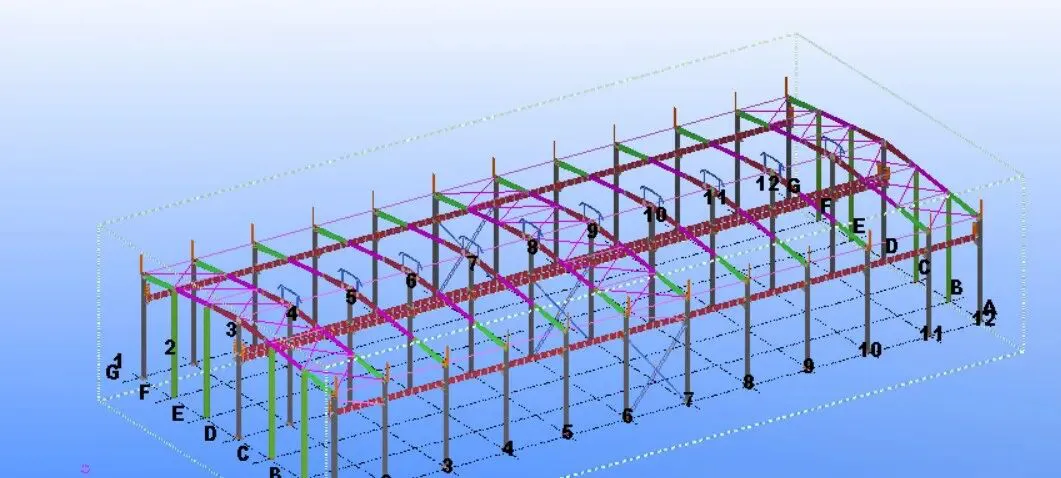

1. Use Advanced Design Software

Design software like Tekla Structures and Revit can help manage the complexities of custom designs by offering 3D modeling and simulation tools. These tools allow you to visualize the structure before construction begins, minimizing the risk of design errors.

2. Cross-Disciplinary Collaboration

Custom steel structures require input from various specialists, including architects, structural engineers, and MEP (Mechanical, Electrical, Plumbing) engineers. Effective communication between all stakeholders is crucial.

3. Risk Assessment and Contingency Planning