Time:2025-11-10 06:58:28 Source:Sanjian Meichen Steel Structure

Steel structure equipment frames are key components in the industrial construction process, especially in fields that require heavy machinery support, such as petrochemicals, power generation, manufacturing, and mining. These structures are engineered to ensure machinery operates safely and efficiently while optimizing space. Whether it's for large-scale machinery installation, material handling, or optimizing facility space, steel structure equipment frames are essential for modern industrial operations.

In this guide, we'll take a closer look at the types of steel structure equipment frames, how they are designed and implemented, and why they are crucial in various industries. We’ll also break down technical terms in simple language, making the article easy to understand for both industry professionals and newcomers.

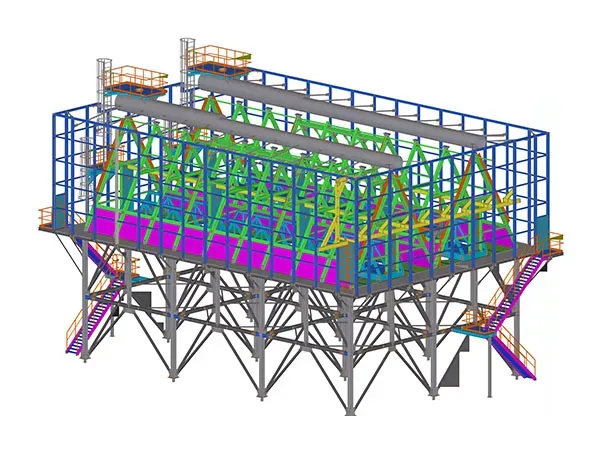

An equipment platform is a large, sturdy structure designed to support and provide access to industrial equipment. These platforms are installed to make the operation, repair, and maintenance of machinery more efficient and safe. Imagine them as elevated floors that hold machinery in place, offering enough space for workers to move around and maintain the equipment.

High Load Capacity: These platforms are designed to hold the weight of large machines and equipment. The material used (typically steel) ensures the platform can handle heavy-duty machines without risk of failure.

Multilevel Design: Depending on the machinery layout, platforms can be designed with multiple levels to optimize space. This feature allows for better access to equipment and offers a space-efficient solution.

Accessibility: Equipped with stairs, handrails, and walkways, equipment platforms provide safe access to the equipment for maintenance staff.

Petrochemical Plants: Equipment platforms are used to hold large-scale machinery such as reactors, compressors, and heat exchangers, providing stable support for their heavy weight.

Power Plants: These platforms are essential for supporting turbines, generators, and other heavy equipment, ensuring workers can maintain them safely.

Manufacturing Facilities: Platforms help support assembly line equipment or machinery used in manufacturing processes, improving workflow and safety.

Equipment platforms allow workers to easily access machinery for routine maintenance, repairs, and upgrades. By having a designated, stable platform, employees can work more efficiently, reducing downtime and improving the overall productivity of the facility.

An equipment support frame is a strong steel structure designed specifically to support large or heavy machinery, ensuring the equipment stays stable during operation. These frames are critical for machines that produce significant vibrations or require consistent support, such as compressors, reactors, or pumps.

Stability and Strength: Designed to handle the static (unchanging) and dynamic (changing during operation) loads generated by large machinery.

Adaptability: Equipment support frames can be customized to fit various machinery types and sizes, providing robust support in different operational environments.

Durability: Made from high-quality steel, these frames are built to last under harsh industrial conditions, withstanding high temperatures, vibration, and other challenges.

Petrochemical and Chemical Plants: Equipment support frames hold core machinery such as reactors, heat exchangers, and compressors, ensuring these critical pieces of equipment remain stable and operational.

Power Plants: These frames provide support for equipment like turbines, pumps, and fans, which are key to the plant’s operation.

Heavy Manufacturing: In industries like steel production, equipment support frames are used to stabilize heavy machines used in production lines.

Without stable support, heavy machinery can experience vibrations that may cause damage, leading to costly repairs and downtime. Equipment support frames help ensure the stability and safe operation of machinery by distributing loads evenly across the structure.

A conveyor gallery (also known as a belt corridor) is a steel framework that houses conveyor belts, often used to move bulk materials like coal, grain, or chemicals across long distances. These galleries can be enclosed or partially enclosed, protecting the conveyor system from weather conditions and external damage.

Long Spans: Conveyor galleries are designed with large spans to support long conveyor systems without the need for too many intermediate supports.

Protection from the Elements: The gallery often features weatherproofing systems to protect the conveyors from environmental elements like rain, snow, and dust.

Truss Structure: Many conveyor galleries utilize trusses to maximize strength and minimize material use while maintaining a stable structure.

Mining Operations: Used to move minerals from mining sites to processing plants over large distances.

Ports and Shipping Facilities: Conveyor galleries facilitate the transport of bulk materials, such as coal or iron ore, from ships to storage facilities or further processing.

Power Plants and Steel Mills: These galleries help move coal, ores, and other materials between production areas.

Conveyor galleries streamline the material transport process, reducing the need for manual labor and allowing for continuous, automated transport. This significantly boosts productivity and reduces operational costs in industries like mining and power generation.

A flare stack support frame is a high, robust steel structure used to support a flare system in petrochemical plants. These stacks are responsible for safely burning off excess gases during operation, ensuring no harmful gases are released into the atmosphere.

Height and Strength: These frames must be tall enough to allow the safe release of gases, while remaining strong enough to endure extreme temperatures, corrosion, and high winds.

Corrosion Resistance: Because flare systems emit harsh gases, these support frames are coated with protective materials to resist corrosion.

Resistance to Seismic and Wind Loads: Flare stack frames are designed to withstand heavy wind loads and seismic activity, ensuring operational safety.

Oil Refineries: Used to safely burn off excess gases during the refining process.

Petrochemical Plants: Essential for safe venting of gases during chemical processing.

Natural Gas Processing Plants: Ensures that gases are burned off in a controlled manner, protecting the facility and the environment.

Flare stack support frames are crucial in maintaining safety by preventing hazardous gas buildup and ensuring compliance with environmental regulations. They provide structural integrity to flare systems, which are vital for safely releasing excess gases.

A steel mezzanine is an additional intermediate floor installed within an industrial building. It provides extra space for storage, equipment, or workstations, maximizing the use of vertical space without expanding the building’s footprint.

Space Efficiency: Steel mezzanines are an excellent solution for facilities that need additional space but don’t want to extend the building.

Flexibility: Mezzanines can be designed to support various functions, such as storage, equipment housing, or even office spaces.

Quick Installation: Steel mezzanines are fast to design and install, minimizing disruption to operations.

Warehouses: Provide additional storage capacity for goods and inventory.

Manufacturing Plants: Offer extra space for equipment, production lines, or assembly areas.

Data Centers: Used to house IT equipment and server racks in elevated areas, optimizing floor space.

Steel mezzanines help businesses optimize vertical space, allowing them to expand storage or operations without the need for costly building expansions. This flexibility leads to better space utilization, which improves overall efficiency and lowers costs.

Steel structure equipment frames are an indispensable part of industrial construction, ensuring the stable support of heavy machinery, efficient material handling, and optimal use of space. Whether it’s an equipment platform, support frame, conveyor gallery, flare stack support, or mezzanine, these structures play a critical role in improving safety, productivity, and cost-effectiveness across a variety of industries.

At MEICHEN STEEL STRUCTURE, we provide customized steel structure solutions tailored to meet the unique needs of your industrial operations. Our expertise in designing, fabricating, and installing steel frames ensures that your equipment operates at maximum efficiency, while also enhancing the safety and longevity of your facility.