Time:2025-04-18 06:06:27 Source:Sanjian Meichen Steel Structure

On the grand canvas of modern architecture, standardized solutions often fail to meet increasingly complex and personalized needs. Whether it is a unique industrial production process, an innovative commercial display space, or a public facility with specific functions, buildings need to go beyond the limitations of "one size fits all". At this time, customized steel structure building frames came into being, which provide tailor-made solutions for various projects with unparalleled flexibility and excellent performance.

Customized steel structure frames not only provide steel, but also provide a full range of services from concept to implementation, aiming to transform the customer's unique vision into a safe, efficient, beautiful and functional physical building. This article will delve into the unique advantages, professional customization process, wide range of application scenarios and the core value it brings to the project of customized steel structure frames, revealing why it is the best choice to realize the dream of exclusive architecture.

Designing steel building frames is a complex engineering task that requires specialized knowledge of structural mechanics, material science, relevant building codes, and analysis software. This process MUST be performed by a qualified and licensed Structural Engineer. This guide provides an overview of the steps involved, not a substitute for professional engineering services.

Customization imbues steel structures with life and individuality, making them stand out from other architectural options.

1.Unparalleled Design Flexibility:

Breaking Spatial Constraints: Whether it's ultra-large spans, non-standard heights, or complex multi-story structures, customized steel structures offer solutions, creating open, column-free spaces unattainable with traditional materials and meeting specific functional requirements (such as large warehouses, stadiums, and aircraft hangars).

Adapting to Complex Terrain and Environments: For irregular plots, undulating terrain, or unique environmental conditions (such as high-wind and seismic zones), customized designs can optimize structural forms and ensure building stability and safety.

Incorporating Unique Architectural Aesthetics: Architects and designers can incorporate their unique creative and aesthetic concepts into the structure, achieving distinctive shapes and facades, and enhancing the building's iconic character.

2. Highly Functional and Efficient Optimization:

Precisely Meeting Operational Needs: Optimizing structural layout based on specific operational requirements, such as factory production line layout, warehouse storage processes, and commercial display routes, improves space utilization and work efficiency. Integrated Multifunctional Systems: Pre-designed interfaces and access points for piping, electrical, ventilation, fire protection, and other equipment enable seamless integration with various building systems, eliminating the hassles and costs of later retrofits.

Optimized Construction Time and Cost: Despite being custom-built, precise factory prefabrication and prefabricated construction effectively control the overall project duration and on-site labor costs, maximizing long-term operational benefits.

3. Superior Structural Performance and Safety:

Precise Mechanical Analysis: Specific mechanical analysis and optimization are performed for specific loads (such as heavy equipment and special stacking loads) and environmental conditions (such as wind and snow loads and seismic loads) to ensure structural safety margins under extreme operating conditions.

High-Quality Materials and Manufacturing: High-quality steel materials that meet design requirements are selected, and strict control is exercised during the factory prefabrication process for machining accuracy, welding quality, and anti-corrosion treatment to ensure component quality from the very beginning.

Meeting Strict Specifications: All custom design and manufacturing adheres strictly to national and international building codes and industry standards to ensure project legal compliance. 1.4 Return on Investment and Future Value:

Customized buildings are often more recognizable, enhancing a company's brand image and asset value.

The structure can provide interfaces for future expansion or renovation, increasing the flexibility of the building's lifecycle.

Phase 1: Project Definition & Conceptualization

Define Project Requirements & Scope:

Building Use & Occupancy: What is the building for (office, warehouse, manufacturing, retail, residential)? This determines live loads, code requirements, and potentially specific functional needs (e.g., crane loads).

Dimensions & Geometry: Length, width, clear height, roof slope, overall shape. Are there mezzanines, specific column-free spans required?

Location: Crucial for determining environmental loads (wind speed, snow load, seismic zone). Also impacts local building codes and foundation design.

Architectural Requirements: Integration with the architectural design, desired aesthetics, cladding type (influences girt/purlin spacing and loads), locations of doors, windows, and other openings.

MEP Integration: Requirements for HVAC, plumbing, electrical systems – routing, openings, equipment weight.

Budget & Schedule: Constraints that influence design choices (material efficiency, complexity).

Select Structural System & Conceptual Layout:

Based on requirements, choose the primary framing type:

Portal Frames (Rigid Frames): Common for warehouses, industrial buildings. Efficient for clear spans. Connections are typically moment-resisting.

Braced Frames: Uses diagonal bracing (tension/compression or tension-only) to resist lateral loads. Columns primarily take axial load, beams take gravity loads. Connections can often be simpler (pinned/shear).

Moment-Resisting Frames: Relies on rigid connections between beams and columns to resist lateral loads. Often used in multi-story buildings where bracing isn't desired architecturally.

Trusses: Efficient for long spans, especially roofs. Composed of smaller members arranged in triangles.

Develop Preliminary Layout: Determine bay spacing (distance between frames), frame spacing (along the building length), column locations, and bracing locations (if applicable). Consider efficiency, architectural constraints, and load paths.

Phase 2: Load Determination & Analysis

Determine Loads (Code Compliance is Mandatory):

Identify and quantify all applicable loads based on relevant building codes (e.g., ASCE 7 in the US, Eurocodes in Europe, National Building Code of Canada).

Dead Loads (DL): Weight of the structure itself (steel frame, roof deck, purlins, girts), plus permanent attachments (cladding, roofing, ceilings, MEP).

Live Loads (LL): Loads from occupancy and use (people, furniture, stored materials, non-permanent equipment). Roof live loads are also specified by code.

Snow Loads (SL): Based on geographic location, elevation, roof slope, exposure factors, and thermal conditions.

Wind Loads (WL): Based on geographic location (basic wind speed), building height, shape, exposure category, and openings. Calculated for various directions.

Seismic Loads (E): Based on geographic location (seismic design category), building importance, structural system type, soil type, and building mass.

Other Loads: Crane loads, collateral loads (sprinklers, ceilings added later), ponding loads, thermal loads, etc.

Load Combinations: Codes specify various combinations of these loads (e.g., 1.2DL + 1.6LL, 1.2DL + 1.0WL + 0.5*LL) that the structure must safely resist.

Perform Structural Analysis:

Create a Structural Model: Build a mathematical model of the proposed frame geometry in structural analysis software (e.g., STAAD.Pro, SAP2000, RISA-3D, ETABS). Assign preliminary member sizes and material properties (steel grade, Young's modulus, etc.).

Apply Loads & Combinations: Apply the calculated loads and specified load combinations to the model.

Run Analysis: The software solves the complex equations (often using Finite Element Method - FEM) to determine:

Internal Forces: Axial forces, shear forces, and bending moments in each member (beams, columns, braces).

Reactions: Forces transferred to the foundations.

Deflections & Drifts: How much the structure moves under load (vertically and laterally).

Phase 3: Member & Connection Design

Design Structural Members (Sizing):

Based on the analysis results (internal forces), select appropriate steel shapes (W-shapes/I-beams, HSS/tubes, Channels, Angles) and sizes for each member.

Code Checks (e.g., AISC 360, Eurocode 3): Verify that the chosen members have sufficient capacity according to design codes:

Strength: Check bending strength, shear strength, axial strength (tension/compression), combined forces. Account for buckling (local buckling, flexural buckling, lateral-torsional buckling).

Serviceability: Check deflections (vertical) and drift (lateral) against code-prescribed or project-specific limits to ensure occupant comfort, prevent damage to non-structural elements, and maintain functionality.

Iteration: If a member fails a check or is overly conservative (too large/heavy), adjust its size and re-run the analysis (as member stiffness affects load distribution). Repeat until all members are safe and reasonably efficient.

Design Connections:

This is a critical and often complex step. Design the joints where members connect (beam-to-column, beam-to-beam, column base, brace connections).

Connection Type: Choose appropriate types (bolted or welded) and configurations (shear tabs, end plates, flange plates, gusset plates) based on the forces (shear, moment, axial) they need to transfer, constructability, and cost.

Code Checks (e.g., AISC 360 Chapter J, Eurocode 3 Part 1-8): Design bolts, welds, plates, and stiffeners to safely transfer the calculated forces. Check bolt shear/tension, bearing on connected parts, weld strength, plate yielding/rupture/buckling, block shear, prying action, etc.

Design Base Plates & Anchorage:

Design the steel base plates that connect the bottom of the columns to the concrete foundation.

Determine plate size and thickness based on column load and bearing pressure limits of the concrete.

Design anchor bolts (size, number, embedment depth) to resist uplift, shear, and moment transferred from the column according to codes (e.g., ACI 318 Appendix

D). Coordinate closely with the foundation engineer.

Phase 4: Documentation & Review

Produce Detailed Drawings & Specifications:

Fabrication Drawings: Detailed drawings for the steel fabricator showing exact member sizes, lengths, cuts, hole locations, weld details, material grades, and connection details. Includes bills of materials (BOM). Often generated using CAD or BIM software (e.g., AutoCAD, Revit, Tekla Structures).

Erection Drawings: Plans, elevations, and sections showing how the fabricated pieces fit together on site. Includes column layout, frame elevations, bracing locations, connection marks, and erection sequences.

Specifications: Written document detailing material requirements (steel grades, bolt grades), fabrication tolerances, welding procedures, surface preparation/coating requirements, quality control measures, and erection procedures.

Review, Stamp, and Coordinate:

Internal Review: Thorough check of calculations, drawings, and specifications by another qualified engineer.

Engineer's Stamp: The responsible licensed Structural Engineer stamps and signs the final design documents, taking legal responsibility for the design's adequacy and code compliance.

Coordination: Share drawings with the architect, MEP engineers, foundation engineer, and contractor to ensure integration and resolve any conflicts.

Permitting: Submit drawings and calculations to the local building authority for review and approval before construction begins.

This comprehensive process ensures that the custom-designed steel building frame is safe, functional, code-compliant, and meets the specific needs of the project.

Our customized services enable us to adapt to a variety of complex and unique building requirements.

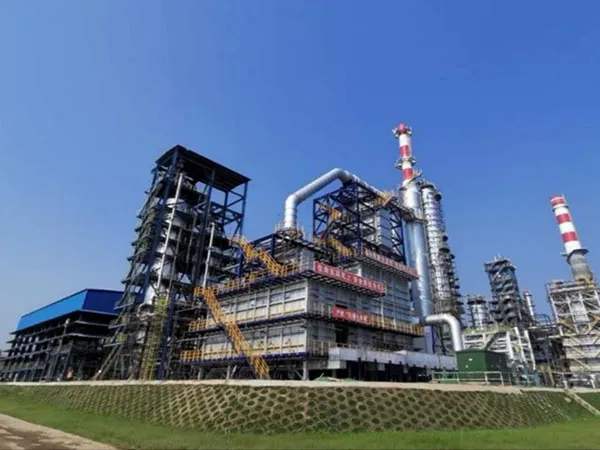

Industrial Facilities: Large-scale production workshops, warehouses, logistics centers, chemical plants, power plants, aircraft hangars, etc., requiring heavy equipment support, large spans, and specialized process flows.

Commercial Buildings: Shopping malls, convention centers, stadiums, theaters, car showrooms, and data centers, achieving unique designs, large spaces, and rapid construction.

Agricultural Buildings: Modern farm storage, livestock breeding facilities, and high-tech greenhouses, offering customized solutions tailored to agricultural production environments.

Public Facilities: Transportation hubs (airports, high-speed rail stations), schools, hospitals, and cultural centers, balancing functionality, safety, and aesthetics.

Special Purpose Buildings: Military facilities, scientific research laboratories, modular camps, and temporary emergency buildings, all with specialized structural requirements.

We are committed to providing exceptional custom steel structure solutions to turn your vision into reality. Professional Engineering and Design Team: Experienced engineers and designers are able to translate your requirements into the optimal structural solution.

Advanced Manufacturing Facilities: Equipped with modern production lines and a strict quality control system, we ensure precision manufacturing and high-quality components.

Full-Process Service: We provide a one-stop, comprehensive solution from project consultation, design, manufacturing, to installation guidance.

Strict Quality Standards: All products and services adhere to the highest international and domestic standards to ensure project safety and durability.

Efficient Project Management: Professional project managers ensure projects are completed on time, on budget, and with high quality.

In the modern construction industry, which strives for uniqueness, functionality, and efficiency, customized steel building frames are undoubtedly a powerful tool for achieving excellence. It's more than just a construction method; it's a collaborative model—seamlessly integrating a client's unique needs with professional engineering technology and advanced manufacturing techniques. Through in-depth and meticulous communication, rigorous and scientific design, meticulous manufacturing, and professional and efficient installation, customized steel building frames can provide the optimal and safest solutions for any complex project, helping companies enhance their competitiveness and create unique landmark buildings. Choosing custom steel structures means choosing quality that exceeds expectations and unlimited architectural possibilities.